After a long-running probe into TikTok, individual states have started to take action against the social media company over security concerns. CNBC’s Kayla Tausche joins ‘Squawk Box’ with the details.

Get the latest international news and world events from around the world.

Tesla AI Day 2 will feature “hardware demos” and tons of technical details: Elon Musk

Tesla CEO Elon Musk recently provided a teaser on what will be happening during the company’s AI Day 2 event this Friday. Considering Musk’s recent comments, it appears that AI Day 2 will be filled to the brim with exciting discussions and demos of next-generation tech.

This is not Tesla’s first AI Day. Last year, the electric vehicle maker held a similar event, outlining the company’s work in artificial intelligence. During the event, Tesla held an extensive discussion on its neural networks, Dojo supercomputer, and humanoid robot, the Tesla Bot (Optimus). Interestingly enough, mainstream coverage of the event later suggested that AI Day was underwhelming or disappointing.

New controversial theory suggests that our past, present and future all exist simultaneously

Here’s an interesting thought. What if you were told that everything in your life has already been planned out?

Even stranger, what if your past, present, and future are all happening right at this moment?

An astonishing new theory known as the “block universe” theory claims that time does not actually “flow like a river”, but rather, everything is ever-present.

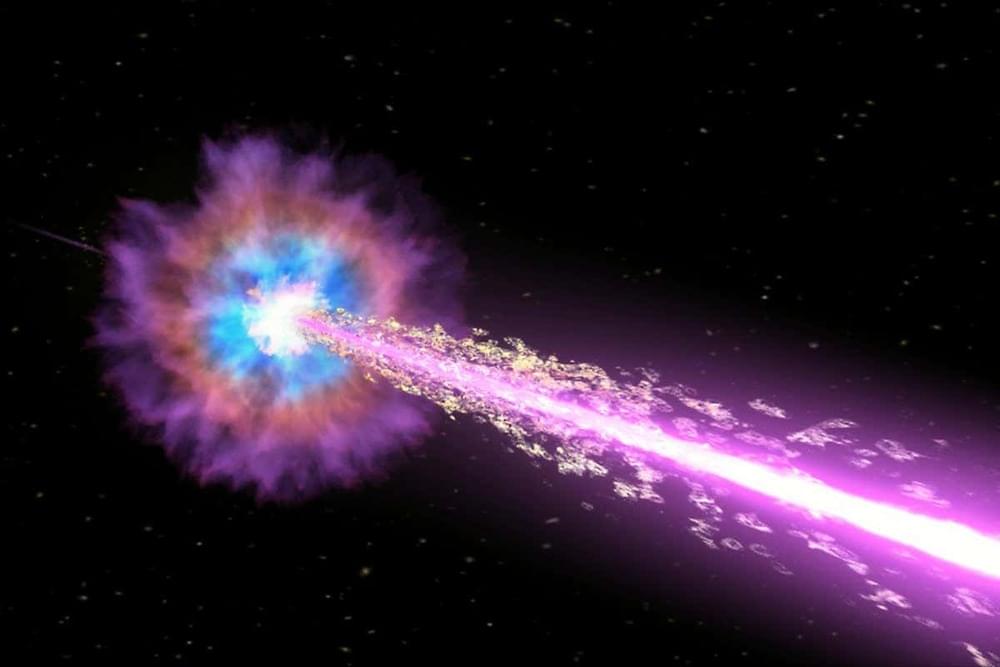

Astronomers have just watched the most powerful explosion ever seen

This type of gamma ray burst (GRB) is thought to occur when a massive star explodes in a supernova, leaving behind a black hole. The explosion creates an extraordinary jet of light which makes up the GRB itself, and then the supernova causes a dimmer afterglow. This particular GRB appears so bright partially because it is about 2.4 billion light years away from Earth, making it one of the closest GRBs ever spotted in addition to being the brightest.

“If we look at all of the gamma ray bursts that have been detected, this one stands apart,” says Jillian Rastinejad at Northwestern University in Illinois. “Informally, we’ve been calling it the BOAT – the brightest of all time.” She and her colleagues calculated that a GRB this bright is expected to occur only once every thousand years or so.

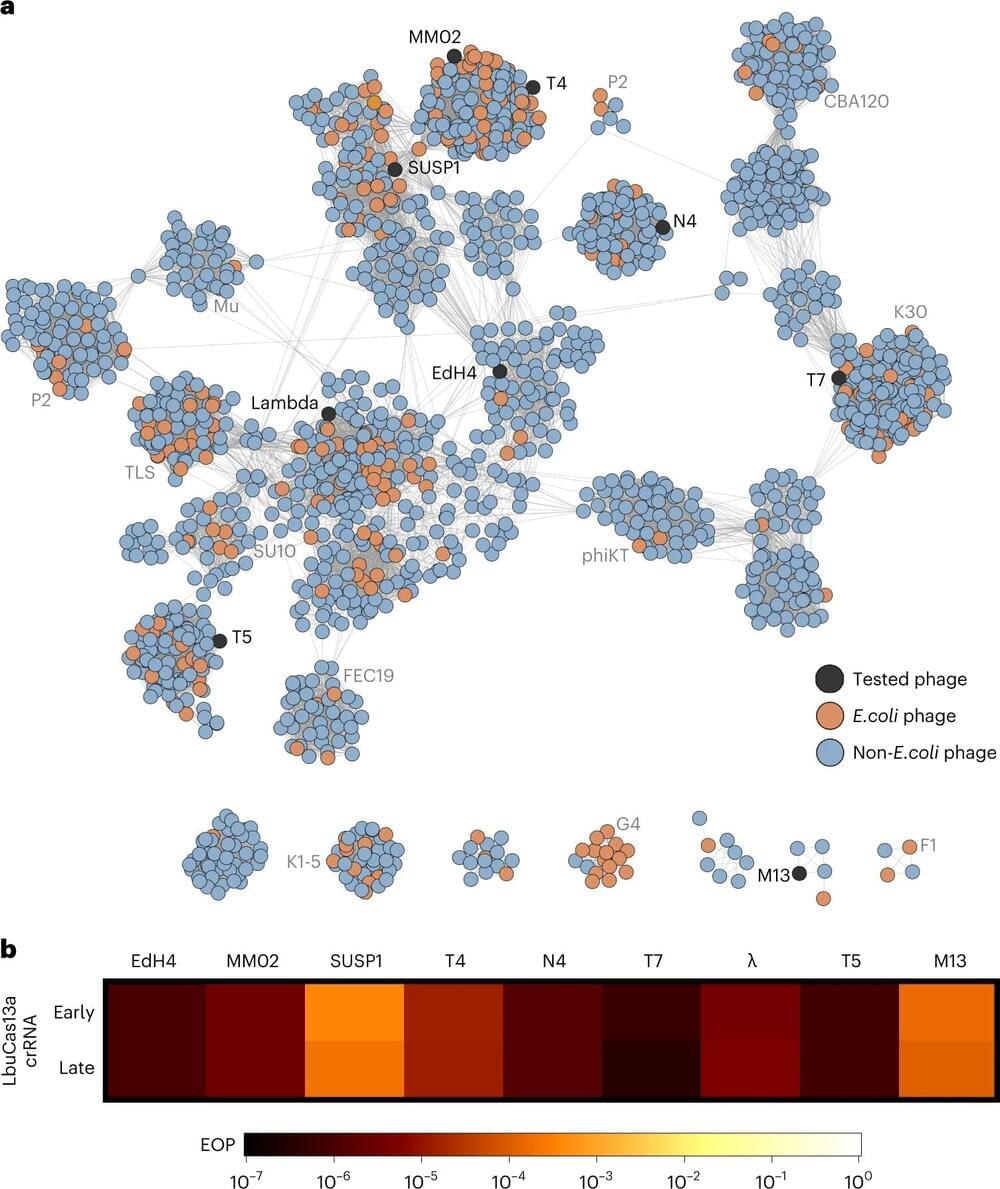

How to edit the genes of nature’s master manipulators

CRISPR, the Nobel Prize-winning gene editing technology, is poised to have a profound impact on the fields of microbiology and medicine yet again.

A team led by CRISPR pioneer Jennifer Doudna and her longtime collaborator Jill Banfield has developed a clever tool to edit the genomes of bacteria-infecting viruses called bacteriophages using a rare form of CRISPR. The ability to easily engineer custom-designed phages —which has long eluded the research community —could help researchers control microbiomes without antibiotics or harsh chemicals, and treat dangerous drug-resistant infections. A paper describing the work was recently published in Nature Microbiology.

“Bacteriophages are some of the most abundant and diverse biological entities on Earth. Unlike prior approaches, this editing strategy works against the tremendous genetic diversity of bacteriophages,” said first author Benjamin Adler, a postdoctoral fellow in Doudna’s lab. “There are so many exciting directions here—discovery is literally at our fingertips.”

‘Quantum time flip’ makes light move simultaneously forward and backward in time

After recombining the superposed photons by sending them through another crystal, the team measured the photon polarization across a number of repeated experiments. They found a quantum interference pattern, a pattern of light and dark stripes that could exist only if the photon had been split and was moving in both time directions.

“The superposition of processes we realized is more akin to an object spinning clockwise and counter-clockwise at the same time,” Strömberg said. The researchers created their time-flipped photon out of intellectual curiosity, but follow-up experiments showed that time flips can be paired with reversible logic gates to enable simultaneous computation in either direction, thus opening the way for quantum processors with greatly enhanced processing power.

Theoretical possibilities also sprout from the work. A future theory of quantum gravity, which would unite general relativity and quantum mechanics, should include particles of mixed time orientations like the one in this experiment, and could enable the researchers to peer into some of the universe’s most mysterious phenomena.

The process algebra model: A new way of constructing reality

The concept of ‘anti-realism’ is widely seen as a fact of life for many physicists studying the mysterious effects of quantum mechanics. However, it also seems to contradict the assumptions of many other fields of research. In his research, Dr William Sulis at McMaster University in Canada explores the issue from a new perspective, by using a novel mathematical toolset named the ‘process algebra model’. In suggesting that reality itself is generated by interacting processes more fundamental than quantum particles, his theories could improve researchers’ understanding of fundamental processes in a wide variety of fields.

The concept of ‘locality’ states that objects and processes can only be influenced by other objects and processes in their immediate surroundings. It is a fundamental aspect of many fields of research and underpins all of the most complex systems we observe in nature, including living organisms. “Biologists and psychologists have known for centuries that the physical world is dominated by processes which are characterized by factors including transformation, interdependence, and information”, Dr Sulis explains. “Organisms are born, develop, continually exchange physical components and information with their environment, and eventually die.”

Beyond biology, the principle of locality also extends to Einstein’s theory of special relativity. Since the speed of light sets a fundamental speed limit on all processes in the universe, the theory states that no process can occur if it has not been triggered by another event in its past, at a close enough distance for light to travel between them within the time separating them. In general, these theories are unified by a concept which physicists call ‘realism’. Yet despite this seemingly intuitive rule, physicists have increasingly come to accept the idea that it doesn’t present a full description of how all processes unfold.