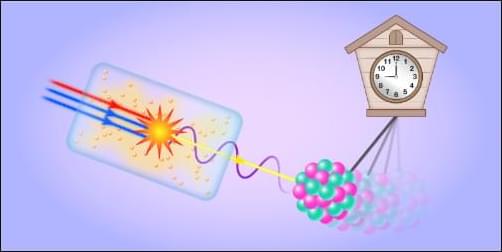

To operate fusion systems safely and reliably, scientists need to monitor plasma fuel conditions and measure properties like temperature and density that can affect fusion reactions. Making these measurements requires specialized sensors known as diagnostics.

A new report sponsored by the U.S. Department of Energy (DOE) recommends increased investment in America’s fusion diagnostic capabilities, a critical new technology that could provide DOE and Congress with information to speed up the delivery of commercial fusion power plants.

The report was produced as part of the DOE’s 2024 Basic Research Needs Workshop on Measurement Innovation, sponsored by the DOE’s Office of Science’s Fusion Energy Sciences (FES) program. It was chaired by Luis Delgado-Aparicio, head of advanced projects at the DOE’s Princeton Plasma Physics Laboratory (PPPL), and co-chaired by Sean Regan, a distinguished scientist and the director of the Experimental Division at the University of Rochester’s Laboratory for Laser Energetics.