The Talon-A2 vehicle air-launched from the world’s biggest aircraft, piloted itself at hypersonic speeds, and landed in California.

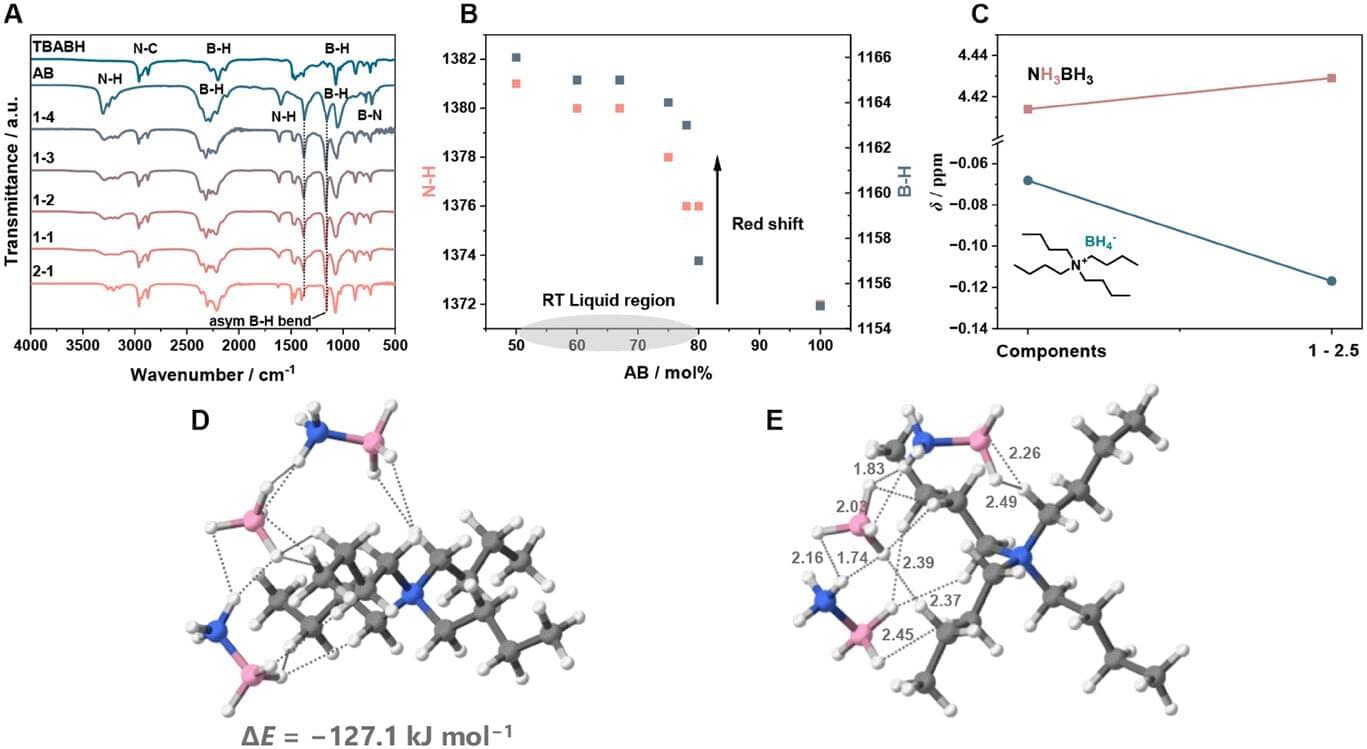

Researchers at EPFL and Kyoto University have created a stable hydrogen-rich liquid formed by mixing two simple chemicals. This breakthrough could make hydrogen storage easier, safer, and more efficient at room temperature.

Hydrogen can be the clean fuel of the future, but getting it from the lab to everyday life isn’t simple. Most hydrogen-rich materials are solids at room temperature, or they only become liquids under extreme conditions like high pressure or freezing temperatures.

Even materials such as ammonia borane, a solid, hydrogen-rich compound that can store a lot of hydrogen, are difficult because they release hydrogen only when heated, often producing unwanted byproducts.

Questions to inspire discussion.

📈 Q: How has Waymo’s crash rate changed over time? A: Waymo’s crash rate increased 8x from 10 to 80 per deployed vehicle between 2024 and 2025, despite only a 2-6x increase in fleet size, indicating a potential decrease in safety.

Operational Insights.

🤖 Q: What proportion of Waymo crashes involved fully autonomous vehicles? A: 521 out of 696 crashes (74.9%) involved fully autonomous vehicles without safety operators, while 167 had an onboard safety operator and 5 had a remote operator.

Market Expansion.

🌎 Q: How has Waymo’s expansion affected its safety record? A: Waymo’s aggressive scaling into new markets like Georgia and Austin, in response to Tesla’s growth, may be contributing to the higher crash rate beyond the increase in deployment rate.

A new leap in lab automation is shaking up how scientists discover materials. By switching from slow, traditional methods to real-time, dynamic chemical experiments, researchers have created a self-driving lab that collects 10 times more data, drastically accelerating progress. This new system not only saves time and resources but also paves the way for faster breakthroughs in clean energy, electronics, and sustainability—bringing us closer to a future where lab discoveries happen in days, not years.

Elon Musk is hinting at revolutionary advancements in AI-generated content, potentially disrupting the gaming industry, with teasers about upcoming Tesla demos and the integration of XAI’s capabilities ## ## Questions to inspire discussion.

Tesla’s Competitive Advantage.

🚗 Q: How does Tesla maintain its lead in autonomous driving? A: Tesla leverages its “data flywheel” built by deploying millions of vehicles to collect real-world data, making it nearly impossible for competitors to replicate.

🤖 Q: What unique combination gives Tesla an edge in AGI development? A: Tesla’s real-world data stream combined with xAI’s language model, voice, video, and image generation capabilities provide the complete recipe for AGI.

Investment Opportunities.

💼 Q: Why do institutional investors undervalue Tesla’s autonomy lead? A: Institutional investors often view Tesla as just a car company, overlooking its unassailable autonomy advantage, while xAI is seen as a pure AI company.

Tesla’s Giga Nevada factory is making significant progress in the production of its Semi trucks and batteries, and is expected to play a major role in the company’s future growth and dominance in the electric vehicle market ## ## Questions to inspire discussion.

Semi-Truck Production.

🚛 Q: What progress is Tesla making on semi-truck trailers at Giga Nevada? A: Tesla is using double drop trailers to haul oversized loads of large machinery, which is a critical step in the factory’s development for semi-truck production.

🔋 Q: How does the LFP battery production at Giga Nevada relate to semi-truck goals? A: The LFP factory is designed to produce 10 gigawatts of stationary batteries annually, which is insufficient for Tesla’s goal of producing 50,000 semi-trucks.

Battery Production.

⚡ Q: What is the current status of battery production at Giga Nevada? A: Battery production is almost ready to begin, with the LFP factory set up to manufacture stationary batteries.

Cybersecurity researchers have discovered a set of four security flaws in OpenSynergy’s BlueSDK Bluetooth stack that, if successfully exploited, could allow remote code execution on millions of transport vehicles from different vendors.

The vulnerabilities, dubbed PerfektBlue, can be fashioned together as an exploit chain to run arbitrary code on cars from at least three major automakers, Mercedes-Benz, Volkswagen, and Skoda, according to PCA Cyber Security (formerly PCAutomotive). Outside of these three, a fourth unnamed original equipment manufacturer (OEM) has been confirmed to be affected as well.

“PerfektBlue exploitation attack is a set of critical memory corruption and logical vulnerabilities found in OpenSynergy BlueSDK Bluetooth stack that can be chained together to obtain Remote Code Execution (RCE),” the cybersecurity company said.

The tests included missions to multiple destinations including Mount Lubań and altitudes of 4,000 feet.

In a test to reach remote locations, the Jetson electric vertical takeoff and landing vehicle reached the summit in fewer than four minutes.

The testing occurred in strong and gusty crosswind conditions peaking at 36 mph.

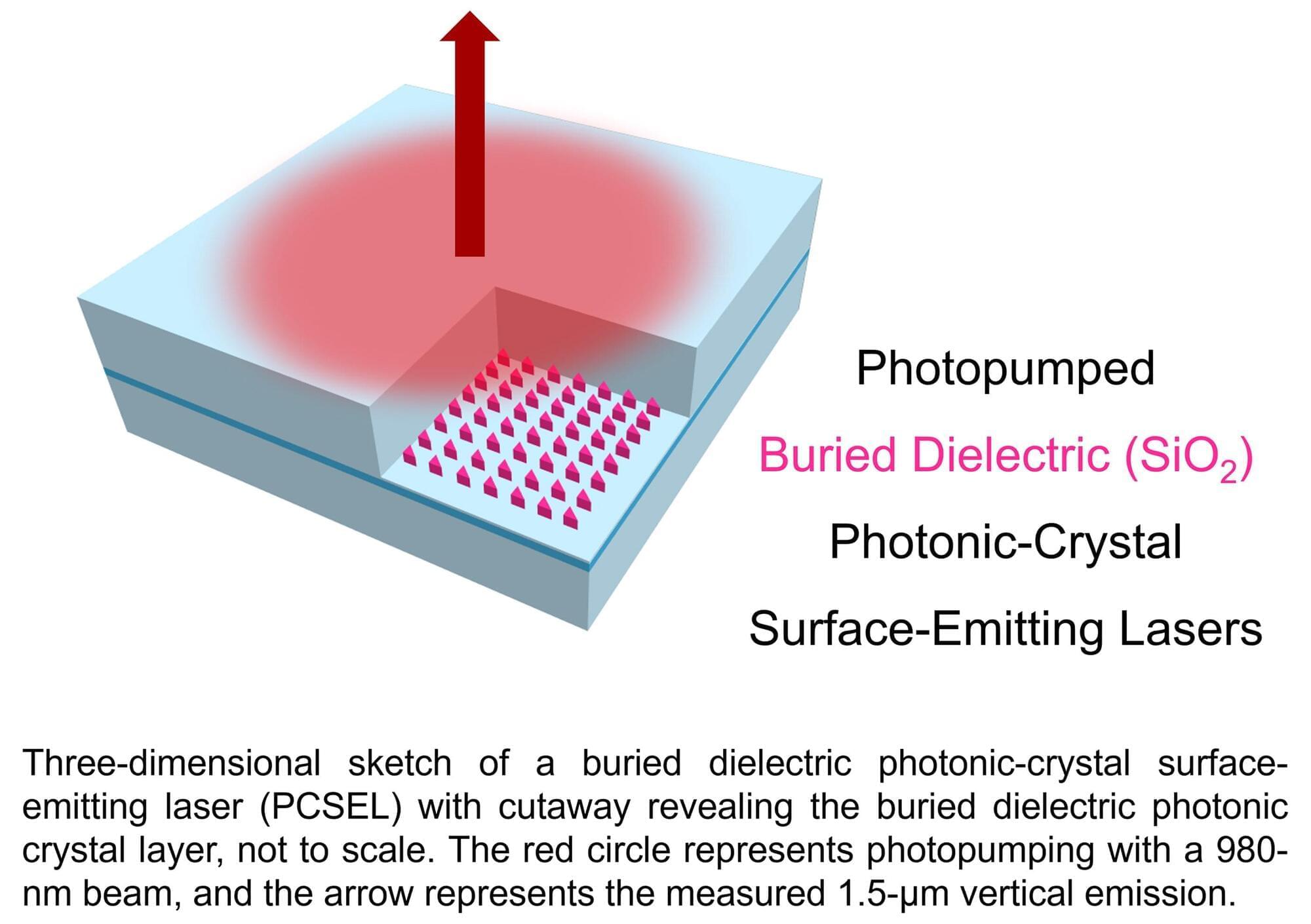

In a first for the field, researchers from The Grainger College of Engineering at the University of Illinois Urbana-Champaign have reported a photopumped lasing from a buried dielectric photonic-crystal surface-emitting laser emitting at room temperature and an eye-safe wavelength. Their findings, published in IEEE Photonics Journal, improve upon current laser design and open new avenues for defense applications.

For decades, the lab of Kent Choquette, professor of electrical and computer engineering, has explored VCSELs, a type of surface-emitting laser used in common technology like smartphones, laser printers, barcode scanners, and even vehicles. But in early 2020, the Choquette lab became interested in groundbreaking research from a Japanese group that introduced a new type of laser called photonic-crystal surface-emitting lasers, or PCSELs.

PCSELs are a newer field of semiconductor lasers that use a photonic crystal layer to produce a laser beam with highly desirable characteristics such as high brightness and narrow, round spot sizes. This type of laser is useful for defense applications such as LiDAR, a remote sensing technology used in battlefield mapping, navigation, and target tracking. With funding from the Air Force Research Laboratory, Choquette’s group wanted to examine this new technology and make their own advancements in the growing field.