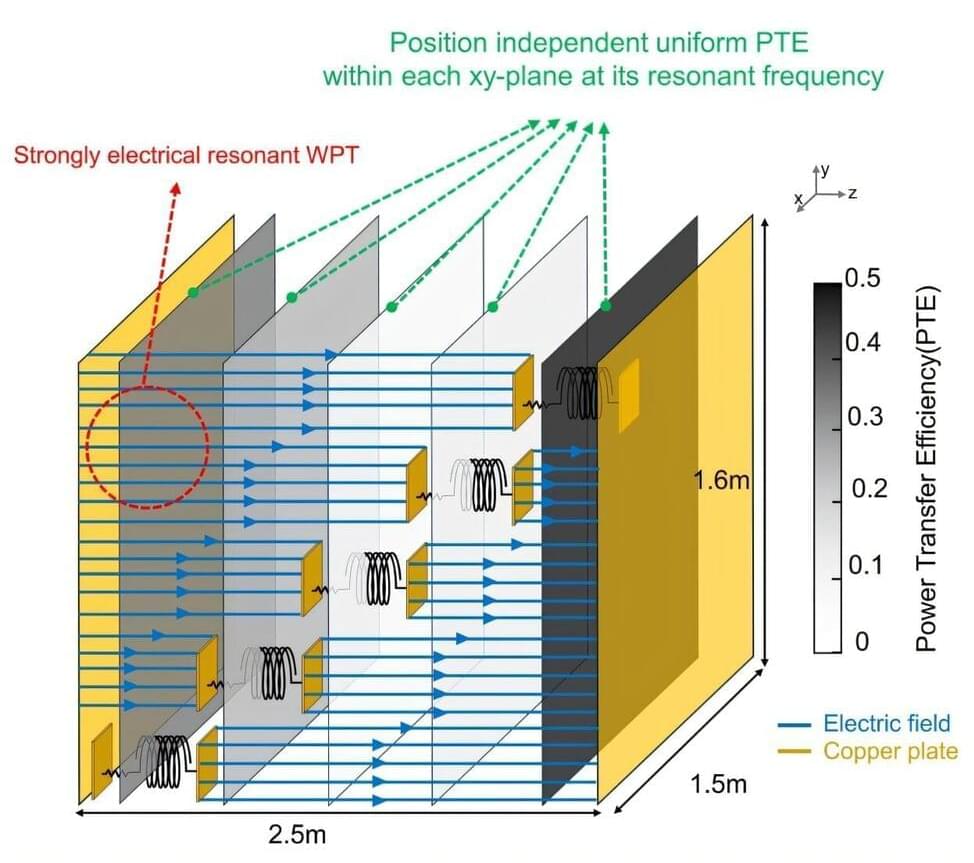

A groundbreaking advancement in technology is paving the way for mobile phones and other electronic devices to recharge simply by being kept in a pocket. This innovative system enables wireless charging throughout three-dimensional (3D) spaces, encompassing walls, floors, and air.

On December 12, Professor Franklin Bien and his research team in the Department of Electrical Engineering at UNIST announced the creation of a revolutionary electric resonance-based wireless power transfer (ERWPT) system, marking a significant milestone in the field. This modern technology allows devices to charge virtually anywhere within a 3D environment, addressing the longstanding challenges associated with traditional magnetic resonance wireless power transfer (MRWPT) and offering a robust solution that enables efficient power transmission without the constraints of precise device positioning.

The paper is published in the journal Advanced Science.