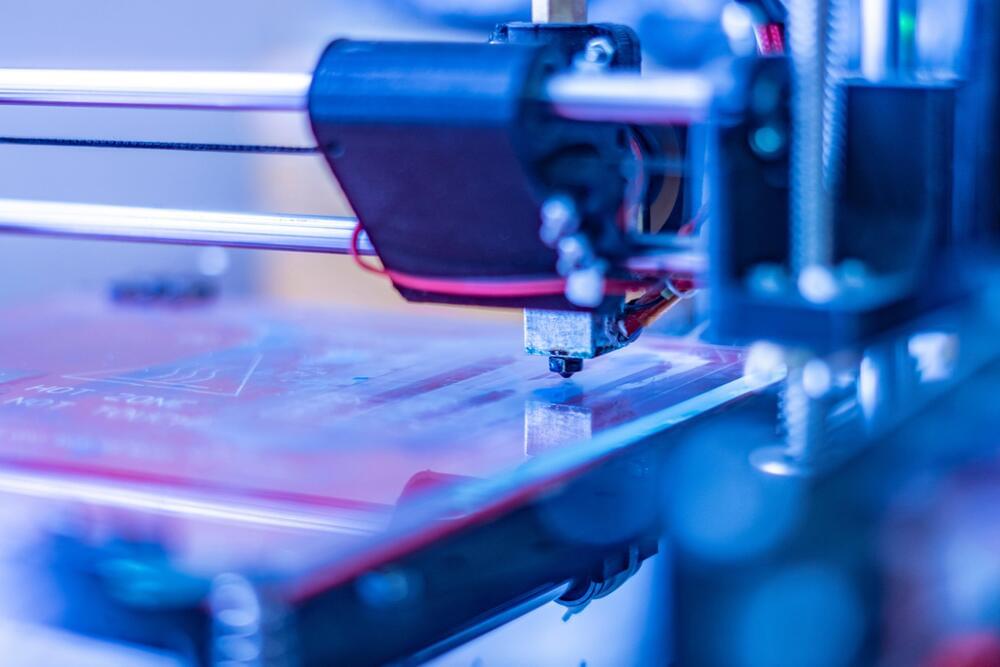

Researchers at the University of Massachusetts Amherst and the Georgia Institute of Technology have 3D printed a dual-phase, nanostructured high-entropy alloy that exceeds the strength and ductility of other state-of-the-art additively manufactured materials, which could lead to higher-performance components for applications in aerospace, medicine, energy and transportation.

The work, led by Wen Chen, assistant professor of mechanical and industrial engineering at UMass, and Ting Zhu, professor of mechanical engineering at Georgia Tech, is published by the journal Nature (“Strong yet ductile nanolamellar high-entropy alloys by additive manufacturing”).

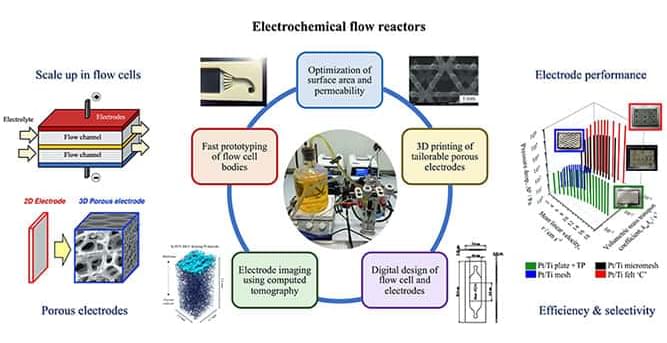

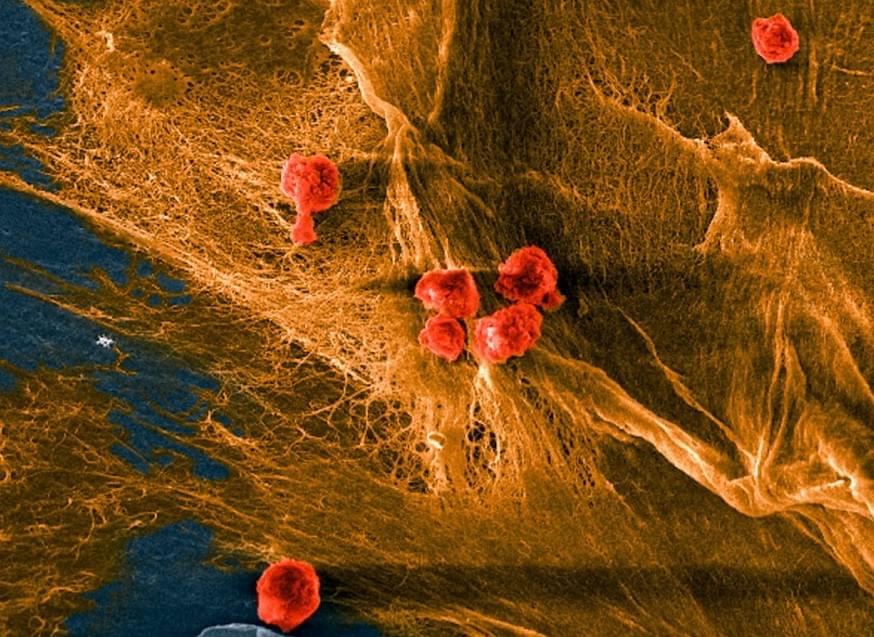

Wen Chen, assistant professor of mechanical and industrial engineering at UMass Amherst, stands in front of images of 3D printed high-entropy alloy components (heatsink fan and octect lattice, left) and a cross-sectional electron backscatter diffraction inverse-pole figure map demonstrating a randomly oriented nanolamella microstructure (right). (Image: UMass Amherst)