Volumetric 3D printing is an exciting technology that could lead to extremely rapid production of 3D printed parts by curing every particle of the object at once. Now, researchers from Utrecht University are applying the process to bioprinting and have 3D printed functioning liver units at centimeter scale in less than 20 seconds. The results were published in Advanced Materials.

Category: 3D printing – Page 36

3D Printing in Breast Reconstruction: From Bench to Bed

Circa 2021:3

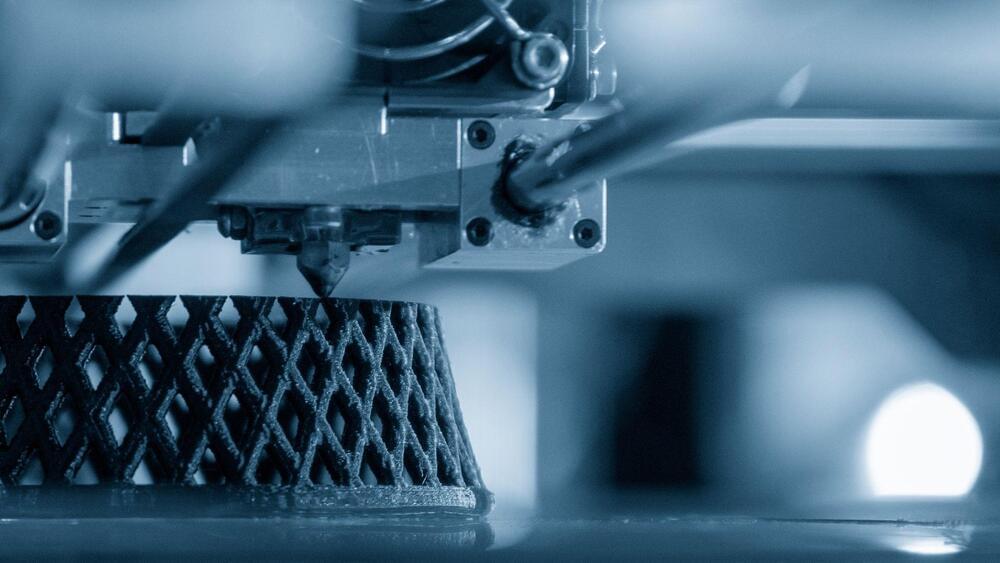

Surgical management of breast cancer often results in the absence of the breast. However, existing breast reconstruction methods may not meet the need for a replacement tissue. Tissue engineering with the use of emerging materials offers the promise of generating appropriate replacements. Three-dimensional (3D) printing technology has seen a significantly increased interest and application in medically-related fields in the recent years. This has been especially true in complex medical situations particularly when abnormal or complicated anatomical surgical considerations or precise reconstructive procedures are contemplated. In addition, 3D bio-printing which combines cells with bio-material scaffolds offers an exciting technology with significant applications in the field of tissue engineering. The purpose of this manuscript was to review a number of studies in which 3D printing technology has been used in breast reconstructive surgical procedures, and future directions and applications of 3D bio-printing.

Breast cancer is the most common cancer diagnosed among US women and is second only to lung cancer as a cause of cancer death among women as of 2019. Because ~268,600 (almost six times than DCIS) new cases prove to be an invasive type of breast cancer (1), many women had to choose the removal of the breast, with immediate consideration for a replacement tissue. Although this was satisfactory in many patients, either saline or gel-filled breast implants (2) do carry real risks of complications such as infection, capsular contracture, implant dislocation, or deformities (3, 4). The option of autologous reconstruction can be more texturally natural aesthetically, but it requires a more complex procedure, significant time and expense, and possible muscle weakness or hernia formation at the tissue donor site (5). Tissue engineering intends to address these limitations by combining the 3D printing technology with synthetic or natural structural elements.

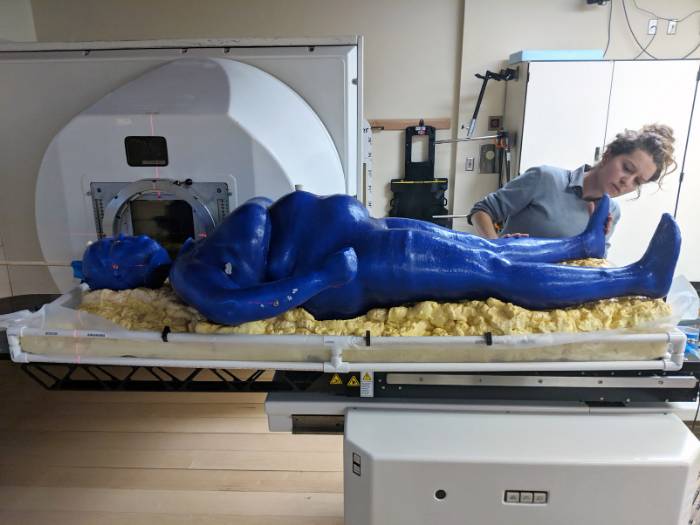

Three-dimensional (3D) printing, also known as computer-aided manufacturing (CAM), was based on digital model files using metal powder or plastic and other adhesive materials to construct objects with a computer guided precision, printing layer upon layer. Simplistically, it uses a computer aided design (CAD) program to convert the virtual model of an object into a printable object using an STL (Standard Tessellation Language or STereoLithography) file. The object then gradually and precisely takes shape as each thin layer is added according to the design file, and composed of the desired material for that object in the form of “ink” using the 3D printer. Not only in cases of intraoperative 3D printed models serving as templates, but this technology has extended to implanted scaffolds that have been used to correct defect-specific sites, clearly enhancing patient treatment (6, 7).

A breakthrough 3D-printed material incredibly strong and ductile

It’s all thanks to nanoclusters.

A new nanoscale 3D printing material developed by Stanford University engineers may provide superior structural protection for satellites, drones, and microelectronics.

A dual-phase, nanostructured high-entropy alloy that has been 3D printed by researchers from the University of Massachusetts Amherst and the Georgia Institute of Technology is stronger and more ductile than other cutting-edge additively manufactured materials. This discovery could lead to higher-performance components for use in aerospace, medicine, energy, and transportation.

High entropy alloys (HEAs), as they are called, have gained popularity as a new paradigm in materials science over the past 15 years. They allow for the creation of a nearly limitless number of different alloy designs since they include five or more elements in nearly equal amounts. Brass, carbon steel, stainless steel, and bronze are examples of traditional alloys that mix a principal element with one or more trace elements.

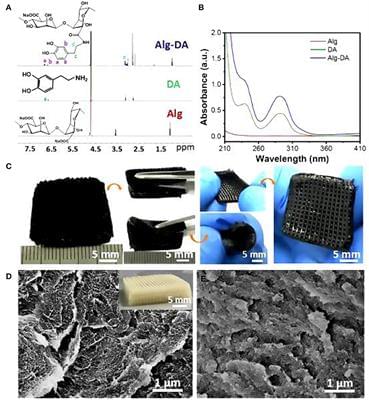

Researchers turn asphaltene into graphene for composites

Asphaltenes, a byproduct of crude oil production, are a waste material with potential. Rice University scientists are determined to find it by converting the carbon-rich resource into useful graphene.

Muhammad Rahman, an assistant research professor of materials science and nanoengineering, is employing Rice’s unique flash Joule heating process to convert asphaltenes instantly into turbostratic (loosely aligned) graphene and mix it into composites for thermal, anti-corrosion and 3D-printing applications.

The process makes good use of material otherwise burned for reuse as fuel or discarded into tailing ponds and landfills. Using at least some of the world’s reserve of more than 1 trillion barrels of asphaltene as a feedstock for graphene would be good for the environment as well.

The Future of Medicine: 3D Printers Can Already Create Human Body Parts

In recent years, updates in 3D printing technologies have allowed medical researchers to print things that were not possible to make using the previous version of this technology, including food, medicine, and even body parts.

In 2018, doctors from the Ontario Veterinary College 3D printed a custom titanium plate for a dog that had lost part of its skull after cancer surgery.

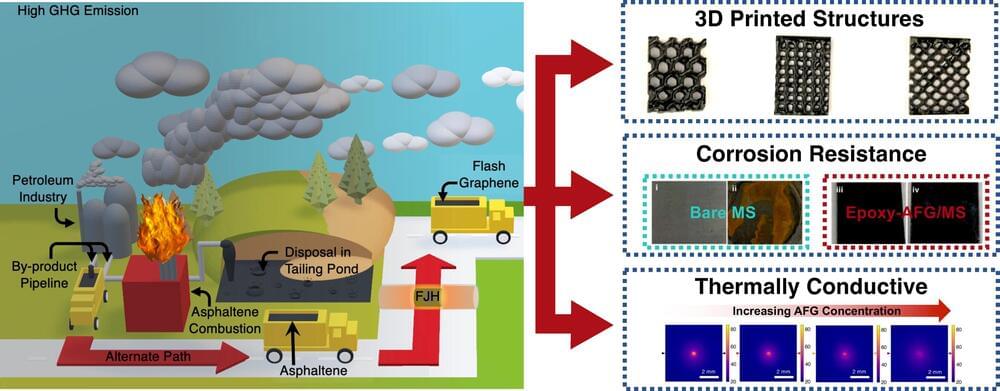

Louisiana State University 3D prints full-body ‘human’ for radiotherapy

face_with_colon_three circa 2018.

Meagan Moore, a Biological and Agricultural Engineering student from Louisiana State University (LSU) has 3D printed a full-size model of the human body for use in radiotherapy.

Such models used in radiotherapy mimic the human tissue, and in medical terms are known as imaging phantoms or phantoms. They are used in radiotherapy to estimate the amount of dose delivery and distribution. A customized phantom of a patient can make the whole process more precise.

3D printing and cancer research

As has been previously reported, 3D printing is being explored by researchers for use in cancer treatment. Earlier this year, Adaptiiv Medical Technologies’ 3D printed bolus was approved for radiation therapy.

Engineers designed a new nanoscale 3D printing material that can be printed at a speed of 100 mm/s

It’s all thanks to nanoclusters.

A new nanoscale 3D printing material developed by Stanford University engineers may provide superior structural protection for satellites, drones, and microelectronicsAn improved lightweight, a protective lattice that can absorb twice as much energy as previous materials of a similar density has been developed by engineers for nanoscale 3D printing.

According to the study led by Stanford University, a nanoscale 3D printing material, which creates structures that are a fraction of the width of a human hair, will enable to print of materials that are available for use, especially when printing at very small scales.

Phuchit/iStock.

An improved lightweight, a protective lattice that can absorb twice as much energy as previous materials of a similar density has been developed by engineers for nanoscale 3D printing.

3D-printing microrobots with multiple component modules inside a microfluidic chip

Scientists from the Department of Mechanical Engineering at Osaka University introduced a method for manufacturing complex microrobots driven by chemical energy using in situ integration. By 3D-printing and assembling the mechanical structures and actuators of microrobots inside a microfluidic chip, the resulting microrobots were able to perform desired functions, like moving or grasping. This work may help realize the vision of microsurgery performed by autonomous robots.

As medical technology advances, increasingly complicated surgeries that were once considered impossible have become reality. However, we are still far away from a promised future in which microrobots coursing through a patient’s body can perform procedures, such as microsurgery or cancer cell elimination.

Although nanotech methods have already mastered the art of producing tiny structures, it remains a challenge to manipulate and assemble these constituent parts into functional complex robots, especially when trying to produce them at a mass scale. As a result, the assembly, integration and reconfiguration of tiny mechanical components, and especially movable actuators driven by chemical energy, remains a difficult and time-consuming process.

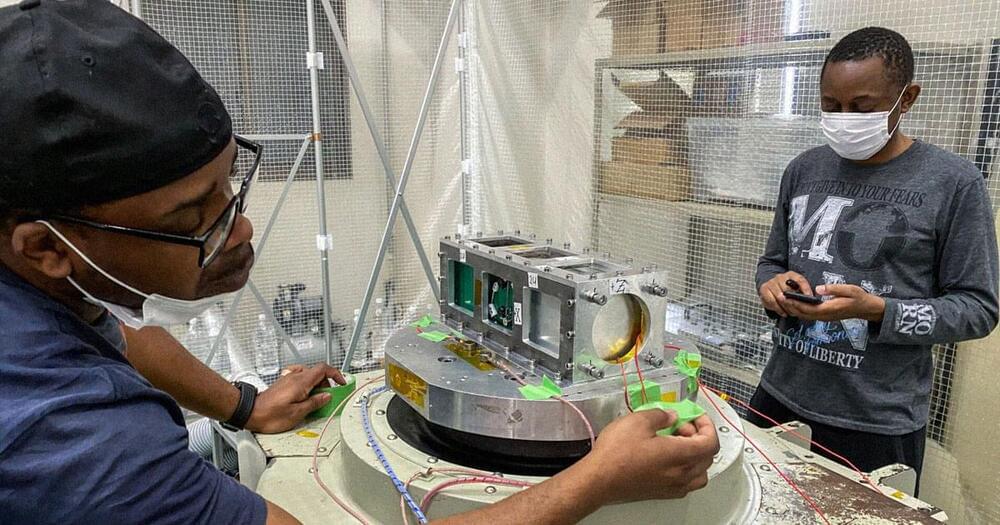

Uganda’s New Satellite Contains Equipment to 3D Print Human Tissue in Orbit

With the help of NASA and Japan, Uganda has officially become a spacefaring nation — and its newly-launched PearlAfricaSat-1 craft has some pretty nifty tech onboard.

As the Uganda-based Nile Post reports, the satellite launched out of NASA’s Mid-Atlantic Regional Spaceport facility in Virginia on the morning of November 7 will not only provide important agricultural and security monitoring features for the developing nation, but will also conduct experiments involving the 3D printing of human tissue.

Per the Ugandan news site, the tissues printed on PearlAfricaSat-1 will be used in research into the effects microgravity has on ovary function — and as Quartz notes in its write-up of the NASA and Japan-supported mission, the microgravity aspect of the experiments is key because “bioprinting” human organs is difficult to achieve with Earth’s gravity.