By using shaped ultrasound, researchers in Germany have developed a way to 3D print objects in one shot.

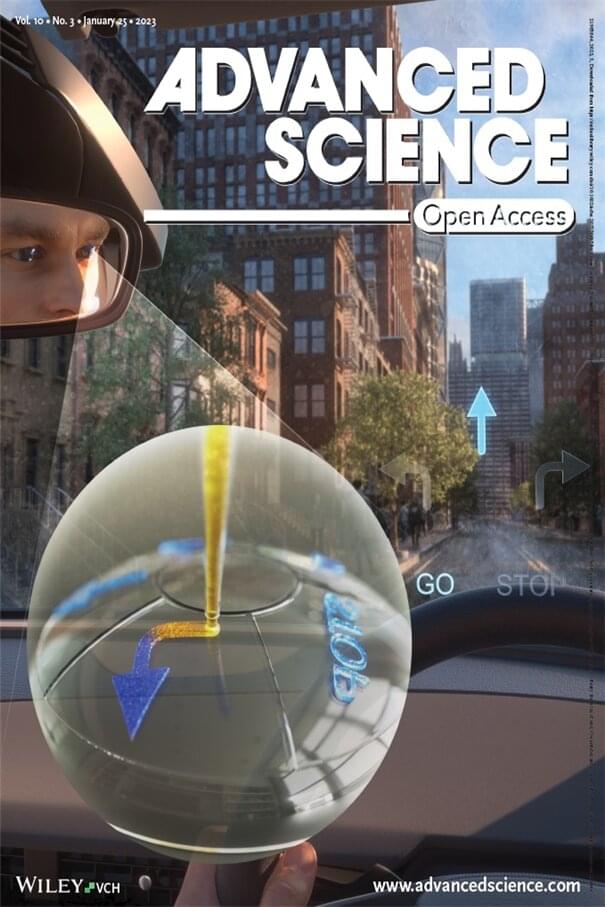

Dr. Seol Seung-Kwon’s Smart 3D Printing Research Team at KERI and Professor Lim-Doo Jeong’s team at Ulsan National Institute of Science and Technology (UNIST) developed core technology for smart contact lenses that can implement augmented reality (AR)-based navigation, with a 3D printing process.

A smart contact lens is a product attached to the human eye like a normal lens that provides various information. Research on these lenses is currently focused mainly on diagnosing and treating health problems. Recently, Google and others are developing smart contact lenses for displays that can implement AR. Yet many obstacles to commercialization exist due to several technical challenges.

In implementing AR with smart contact lenses, electrochromic displays that can be driven with low power are necessary, and a “pure Prussian blue” color, with cost competitiveness and quick contrast and transition between colors, is attracting attention as the lens’ material. In the past, the color was coated on the substrate in the form of a film using the electric plating method, which limited the production of advanced displays that can express various information (letters, numbers, images).

Researchers have come up with a new way to use 3D printing to make a new superalloy.

A group of researchers has developed a new superalloy resistant to high temperatures. This could if ever brought into production, prove revolutionary for the future of turbines.

This would increase its efficiency and decrease waste heat.

Craig Fritz/Sandia Labs.

At present, steam turbine blades, bearings, and seals are made of metal that tends to soften and elongate well before its melting point, which is one issue restricting the output of today’s power plants. If these issues are resolved, it is possible to increase the temperature of anything that uses a steam turbine to convert heat into electricity.

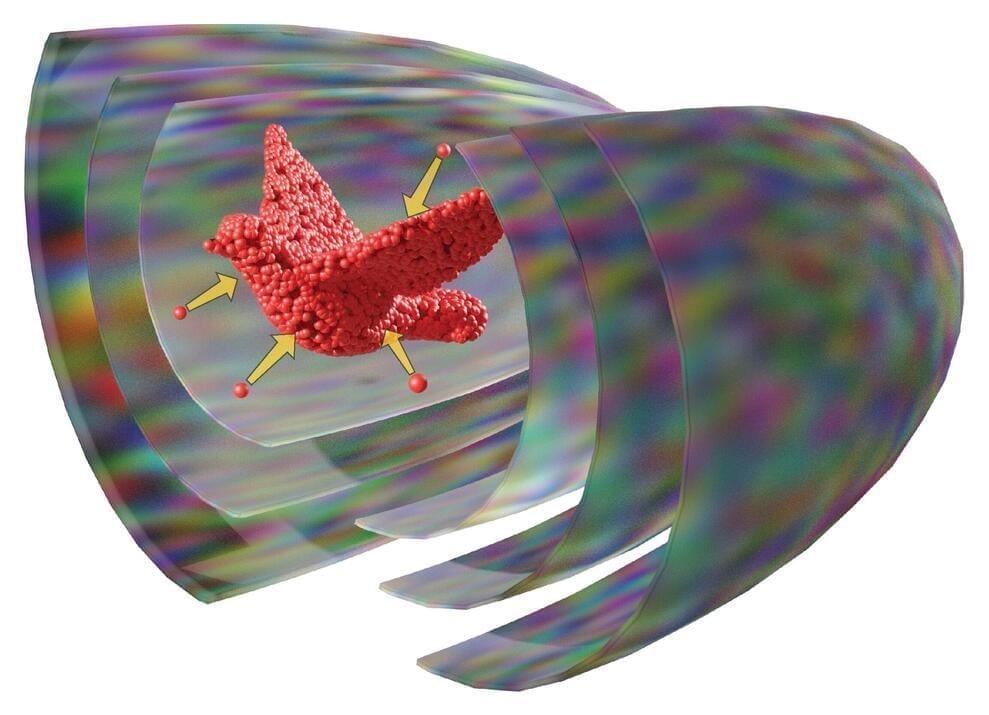

Scientists from the Micro, Nano and Molecular Systems Lab at the Max Planck Institute for Medical Research and the Institute for Molecular Systems Engineering and Advanced Materials at Heidelberg University have created a new technology to assemble matter in 3D. Their concept uses multiple acoustic holograms to generate pressure fields with which solid particles, gel beads and even biological cells can be printed.

These results pave the way for novel 3D cell culture techniques with applications in biomedical engineering. The results of the study were published in the journal Science Advances.

Additive manufacturing or 3D printing enables the fabrication of complex parts from functional or biological materials. Conventional 3D printing can be a slow process, where objects are constructed one line or one layer at a time. Researchers in Heidelberg and Tübingen now demonstrate how to form a 3D object from smaller building blocks in just a single step.

Top 10 upcoming future technologies | trending technologies | 10 upcoming tech.

Future technologies are currently developing at an acclerated rate. Future technology ideas are being converted into real life at a very fast pace.

These Innovative techs will address global challenges and at the same time will make life simple on this planet. Let’s get started and have a look at the top technologies of the future | Emerging technologies.

#futuretechnologies #futuretech #futuristictechnologys #emergingtechnologies #technology #tech #besttechnology #besttech #newtechnology #cybersecurity #blockchain #emergingtech #futuretechnologyideas #besttechnologies #innovativetechs.

Chapters.

00:00 ✅ Intro.

00:23 ✅ 10. Genomics: Device to improve your health.

01:13 ✅ 09. New Energy Solutions for the benefit of our environment.

01:53 ✅ 08. Robotic Process Automation: Technology that automates jobs.

02:43 ✅ 07. Edge Computing to tackle limitations of cloud computing.

03:39 ✅ 06. Quantum Computing: Helping to stop the spread of diseases.

04:31 ✅ 05. Augmented reality and virtual reality: Now been employed for training.

05:05 ✅ 04. Blockchain: Delivers valuable security.

05:50 ✅ 03. Internet of things: So many things can connect to the internet and to one another.

06:40 ✅ 02. Cyber Security to improve security.

07:24 ✅ 01. 3D Printing: Used to create prototypesfuturistic technologybest future tech.

Here at Tech Buzzer, we ensure that you are continuously in touch with the latest update and aware of the foundation of the tech industry. Thank you for being with us. Please subscribe to our channel and enjoy the ride.

Is Director of the Division of Research, Innovation and Ventures (DRIVe — https://drive.hhs.gov/) at the Biomedical Advanced Research and Development Authority (https://aspr.hhs.gov/AboutASPR/ProgramOffices/BARDA/Pages/default.aspx), a U.S. Department of Health and Human Services (HHS) office responsible for the procurement and development of medical countermeasures, principally against bioterrorism, including chemical, biological, radiological and nuclear (CBRN) threats, as well as pandemic influenza and emerging diseases.

Dr. Patel is committed to advancing high-impact science, building new products, and launching collaborative programs and initiatives with public and private organizations to advance human health and wellness. As the DRIVe Director, Dr. Patel leads a dynamic team built to tackle complex national health security threats by rapidly developing and deploying innovative technologies and approaches that draw from a broad range of disciplines.

Dr. Patel brings extensive experience in public-private partnerships to DRIVe. Prior to joining the DRIVe team, he served as the HHS Open Innovation Manager. In that role, he focused on advancing innovative policy and funding solutions to complex, long-standing problems in healthcare. During his tenure, he successfully built KidneyX, a public-private partnership to spur development of an artificial kidney, helped design and execute the Advancing American Kidney Health Initiative, designed to catalyze innovation, double the number of organs available for transplant, and shift the paradigm of kidney care to be patient-centric and preventative, and included a Presidential Executive Order signed in July 2019. He also created the largest public-facing open innovation program in the U.S. government with more than 190 competitions and $45 million in awards since 2011.

Prior to his tenure at HHS, Dr. Patel co-founded Omusono Labs, a 3D printing and prototyping services company based in Kampala, Uganda; served as a scientific analyst with Discovery Logic, (a Thomson Reuters company) a provider of systems, data, and analytics for real-time portfolio management; and was a Mirzayan Science and Technology Policy Fellow at The National Academies of Science, Engineering, and Medicine. He also served as a scientist at a nanotechnology startup, Kava Technology.

Dr. Patel holds a US patent issued in 2005 and has authored over a dozen peer-reviewed articles in areas such as nanotechnology, chemistry, innovation policy, and kidney health.

Dr. Patel earned his Ph.D. in physical chemistry from the Georgia Institute of Technology, and has a bachelor’s degree in chemistry from Washington University in St. Louis.

Pilonnel noticed that millions watch his videos, but very few actually attempt them. He wants to help people by making replacement parts available.

Users of Apple’s AirPods are well aware that the product they purchased is pretty much disposable. Once the rechargeable battery on the device gives way, there is no way to replace them; you need to buy new AirPods, unless you are ready to do the hard work yourself, with a little help, of course.

Ken Pillonel is no stranger to toying with Apple products. As an engineering student, he built the world’s first iPhone with a USB-C port and has previously shown us how the batteries in the AirPods can be replaced if you can 3D-print a new case.

Exploring the Simulation/YouTube.

The best part of Pillonel’s mods is that everything is published in GitHub repositories, and one only needs to spend some time going through the notes to get the desired changes.

I have said 3D printed houses could help with the housing crisis.

“Project Milestone serves as the world’s first 3D printed concrete “commercial housing project,” according to its maker.”

But not according to ICON 3D, and the link below shows Africa’s largest 3D printing housing project in Kenya. I have been talking about 3D printed houses for years. Its good people have caught up.

I also would like to connect with covid in the link below. Check them out as well.

I have said 3D printed houses could help with the housing crisis.

“Project Milestone serves as the world’s first 3D printed concrete “commercial housing project,” according to its maker.”

But not according to ICON 3D, and the link below shows Africa’s largest 3D printing housing project in Kenya. I have been talking about 3D printed houses for years. Its good people have caught up.

I also would like to connect with covid in the link below. Check them out as well.

‚400 a month— see what it’s like to live in” | >

Technology has already changed our world. I mean, who knew that we’d be able to flick a switch to illuminate the darkness rather than lighting a candle? It’s wild. But the technology we have today and will have in the future is absolutely insane. From 3D printing houses to robotics to help us in our jobs, here are 20 emerging technologies that will change our world.

► For copyright matters please contact us: [email protected]