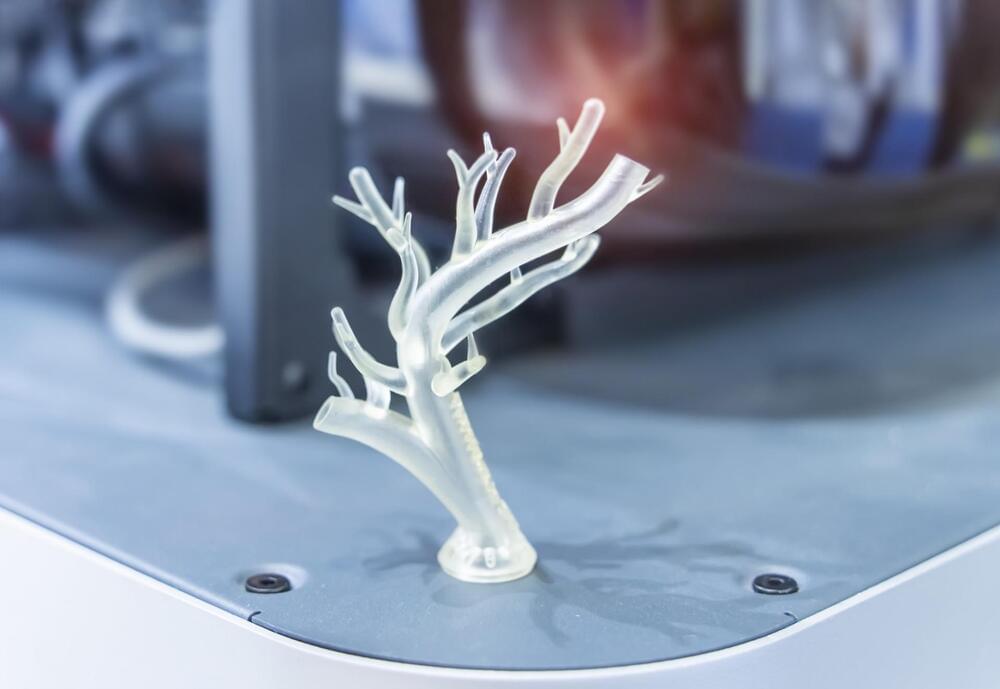

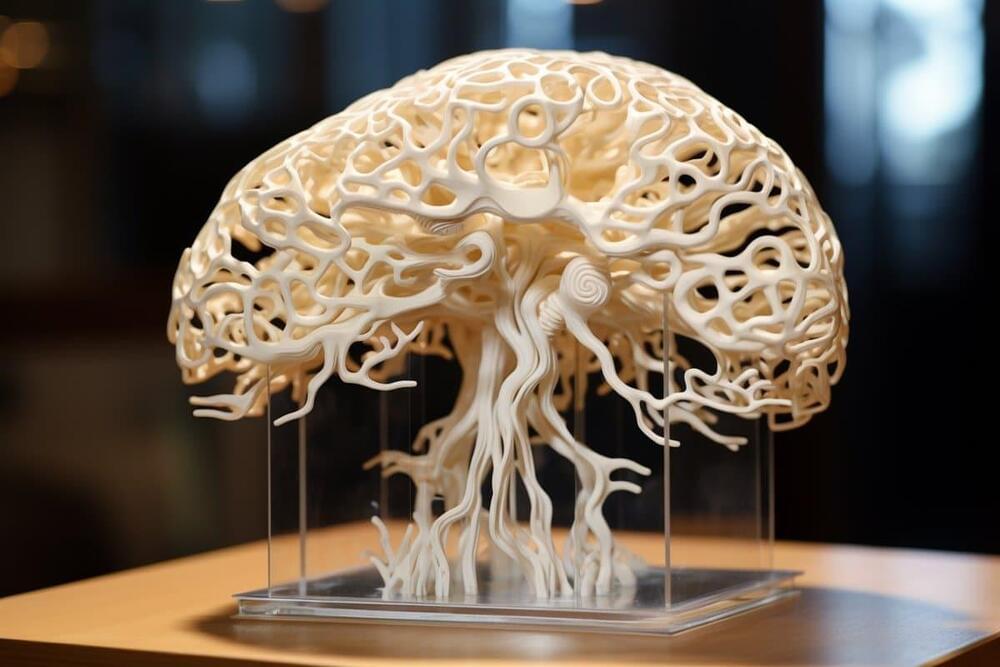

Imagine being able to build an entire dialysis machine using nothing more than a 3D printer.

This could not only reduce costs and eliminate manufacturing waste, but since this machine could be produced outside a factory, people with limited resources or those who live in remote areas may be able to access this medical device more easily.

While multiple hurdles must be overcome to develop electronic devices that are entirely 3D printed, a team at MIT has taken an important step in this direction by demonstrating fully 3D-printed, three-dimensional solenoids.