The Department of Energy’s Oak Ridge National Laboratory has publicly released a new set of additive manufacturing data that industry and researchers can use to evaluate and improve the quality of 3D-printed components. The breadth of the datasets can significantly boost efforts to verify the quality of additively manufactured parts using only information gathered during printing, without requiring expensive and time-consuming post-production analysis.

Data has been routinely captured over a decade at DOE’s Manufacturing Demonstration Facility, or MDF, at ORNL, where early-stage research in advanced manufacturing coupled with comprehensive analysis of the resulting components has created a vast trove of information about how 3D printers perform. Years of experience pushing the boundaries of 3D printing with novel materials, machines and controls have provided ORNL with the unique ability to develop and share comprehensive datasets. The newest dataset is now available for free through an online platform.

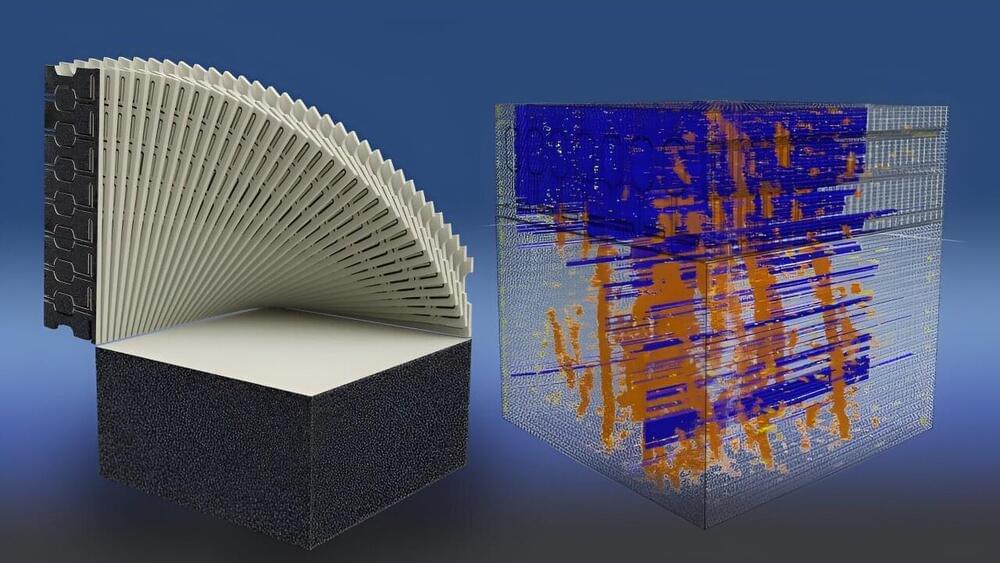

The conventional manufacturing industry benefits from centuries of quality-control experience. However, additive manufacturing is a newer, non-traditional approach that typically relies on expensive evaluation techniques for monitoring the quality of parts. These techniques might include destructive mechanical testing or non-destructive X-ray computed tomography, which creates detailed cross-sectional images of objects without damaging them.

Leave a reply