Faster and better method around Q-dots development which ultimately extends the quality of Quantum Dots plus mass production of Q-Dots is much faster through this new method. Hoping this causes the costs of new cameras, phone displays, monitors/ video displays are now able to be created more cheaply and in larger quantities.

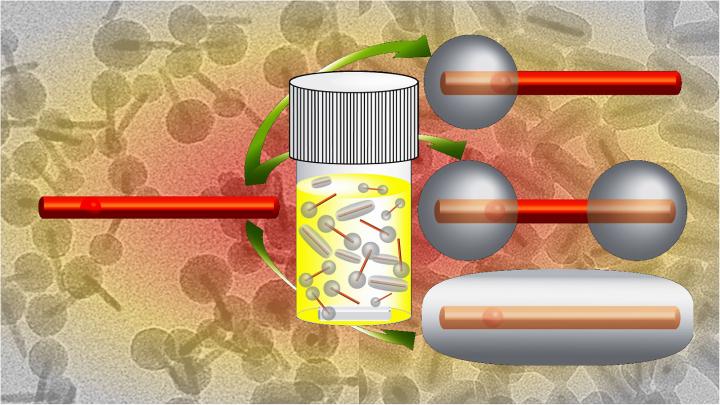

Materials researchers at North Carolina State University have fine-tuned a technique that enables them to apply precisely controlled silica coatings to quantum dot nanorods in a day — up to 21 times faster than previous methods. In addition to saving time, the advance means the quantum dots are less likely to degrade, preserving their advantageous optical properties.

Quantum dots are nanoscale semiconductor materials whose small size cause them to have electron energy levels that differ from larger-scale versions of the same material. By controlling the size of the quantum dots, researchers can control the relevant energy levels — and those energy levels give quantum dots novel optical properties. These characteristics make quantum dots promising for applications such as opto-electronics and display technologies.

But quantum dots are surrounded by ligands, which are organic molecules that are sensitive to heat. If the ligands are damaged, the optical properties of the quantum dots suffer.