Thanks for watching!! Comment Anything As Ud Like!!

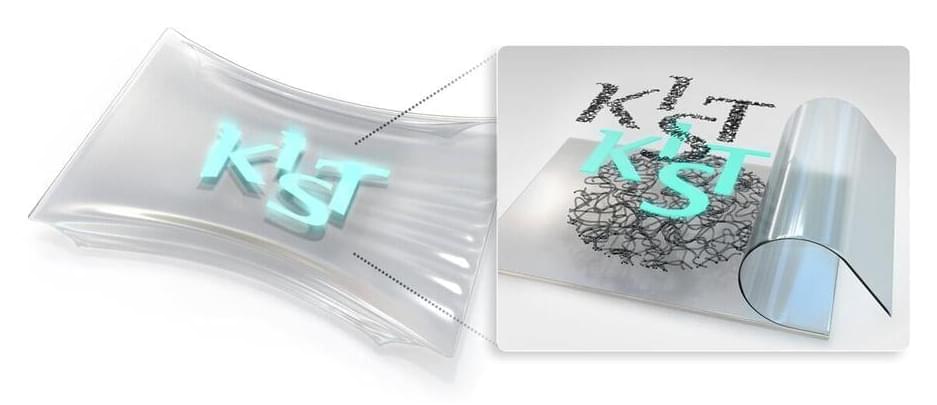

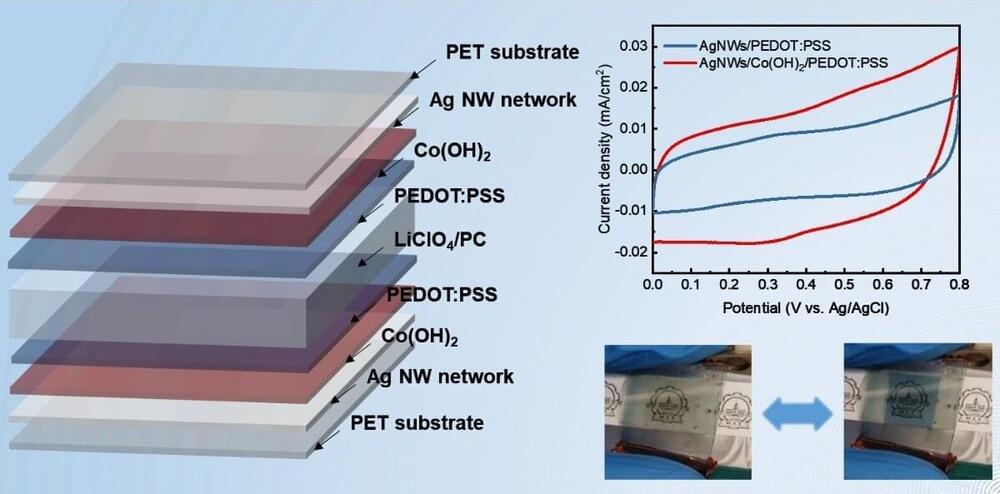

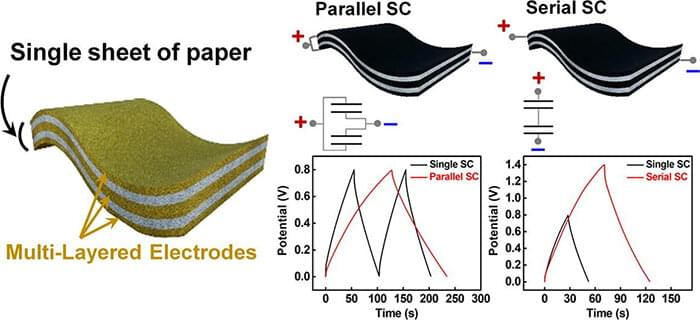

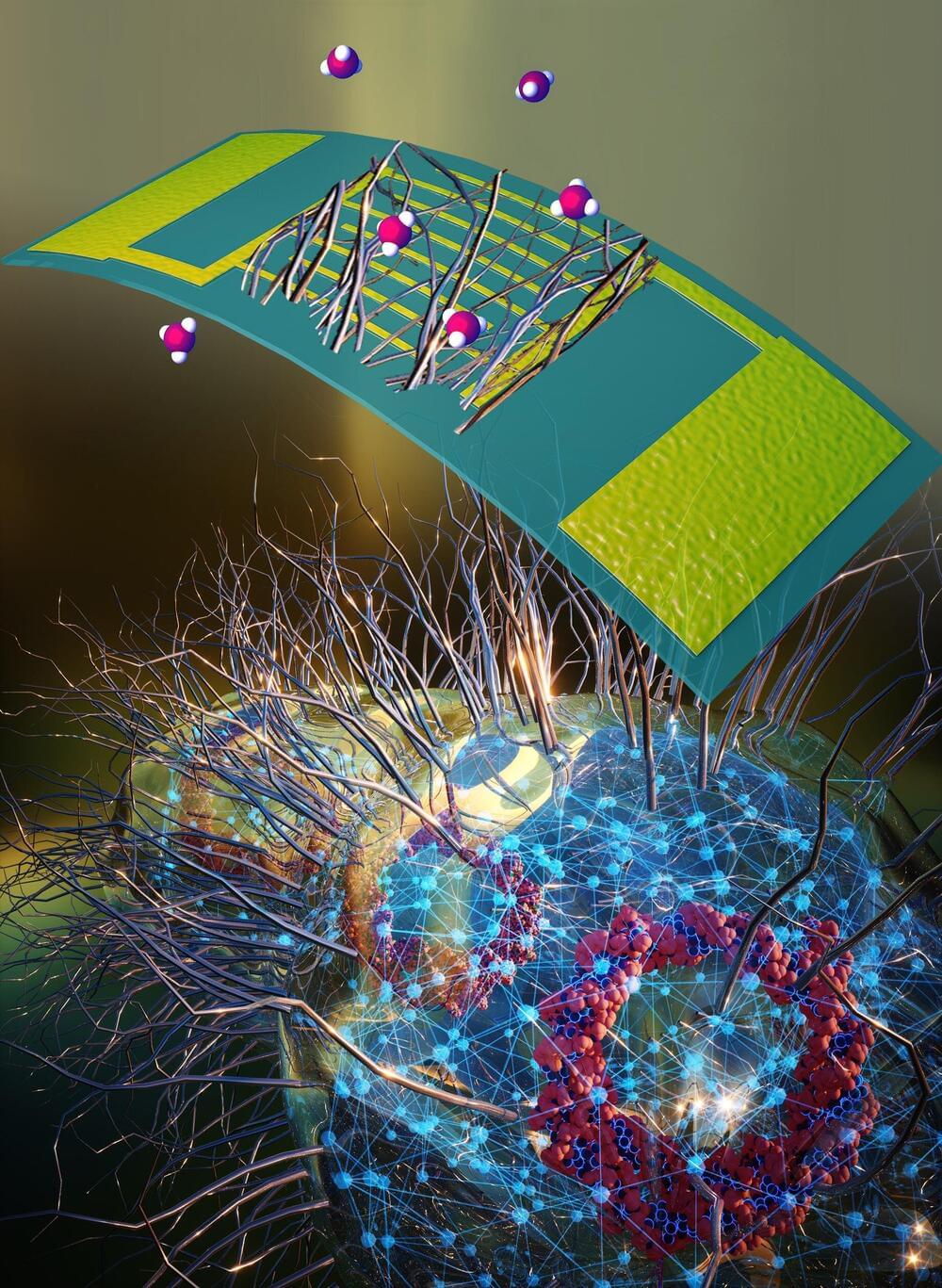

In this educational film scientists and engineers explain the construction of materials beginning at an atomic scale.

NO.5 Documentaries 2017 — How Will Nanotechnology Change the World Documentaries 2017 — How Will Nanotechnology Change the World Documentaries.

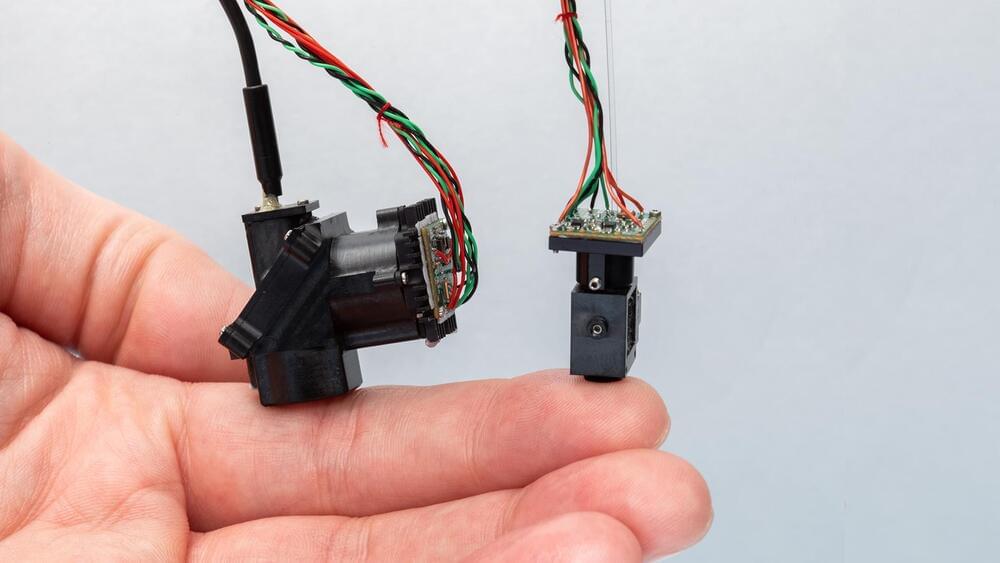

Documentary National Geographic Future Wearable NanoTechnology 2017 Future Are Here BBC Documentary Full.

Winner Best short film at the Scinema Science film festival 2017. Where and what is nano? How will it shape our future? Nanoscience is the study of.