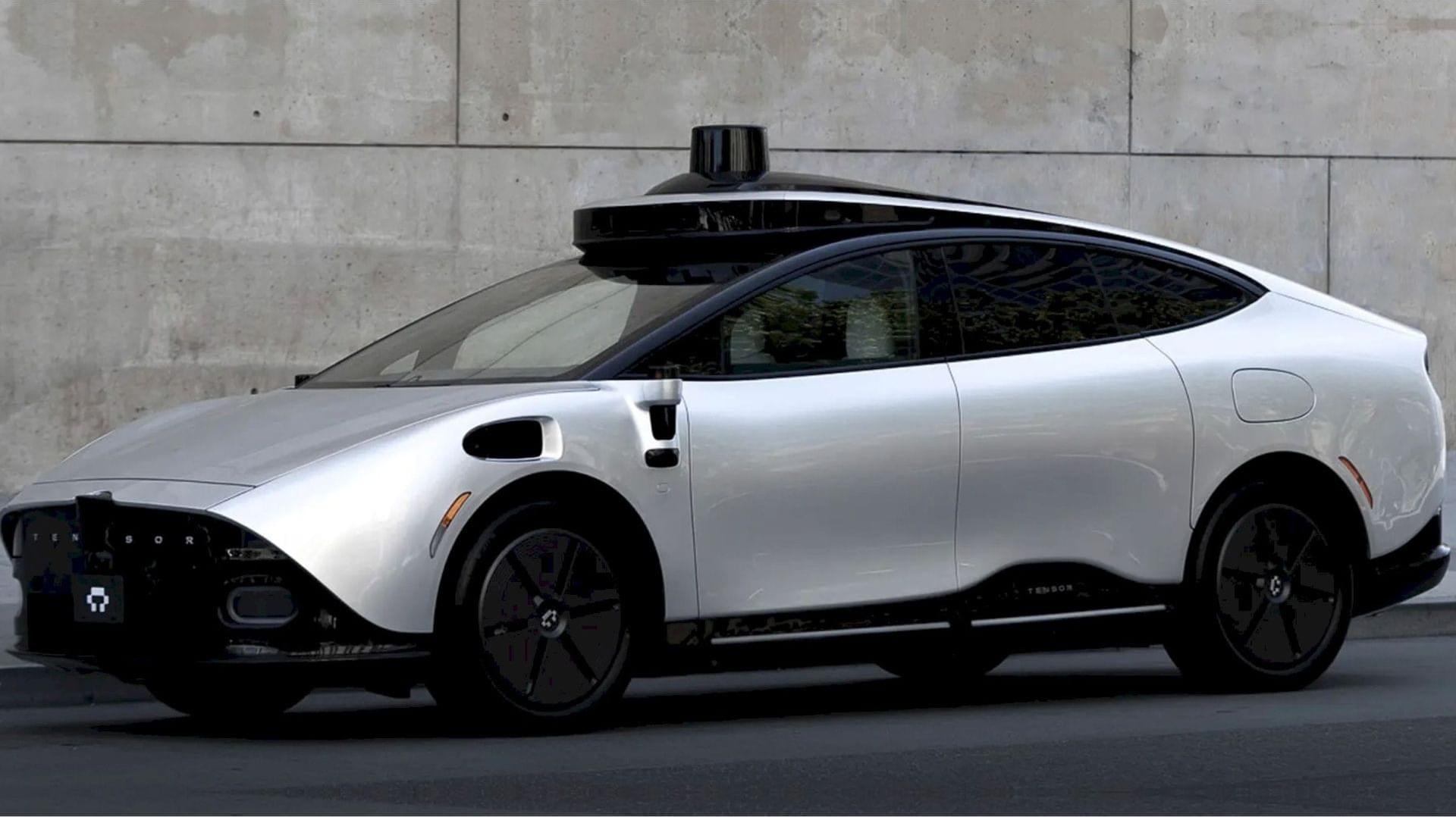

Electric concept car’s fabrics illuminate as it rockets 0–62 mph in just 2 seconds.

This electric concept car can reach 62 mph in just two seconds and will be playable in Gran Turismo 7.

Why modern planes still crash, and how each tragedy reshapes aviation safety.

Why don’t planes crash as often anymore? Because every wreckage becomes tomorrow’s blueprint for safer skies.

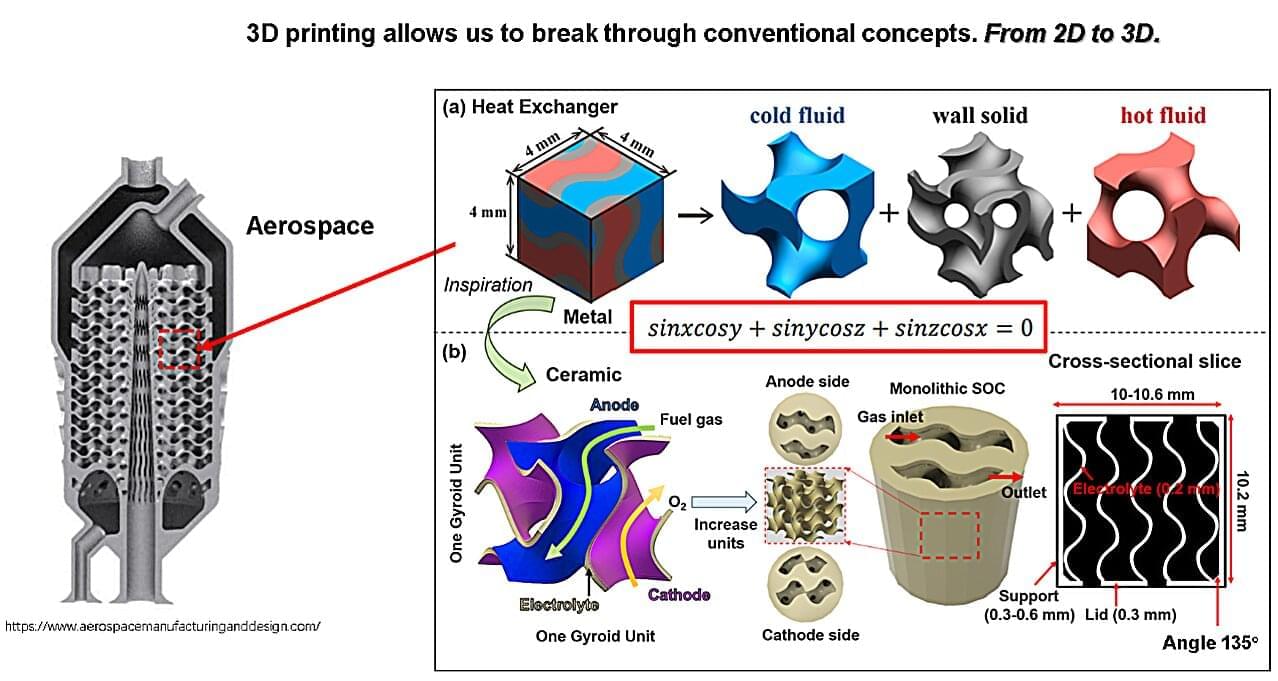

Over the past decades, energy engineers have been developing a wide range of new technologies that could power electronic devices, robots and electric vehicles more efficiently and reliably. These include solid oxide cells (SOCs), electrochemical devices that can operate in two different modes, as fuel cells or as electrolyzers.

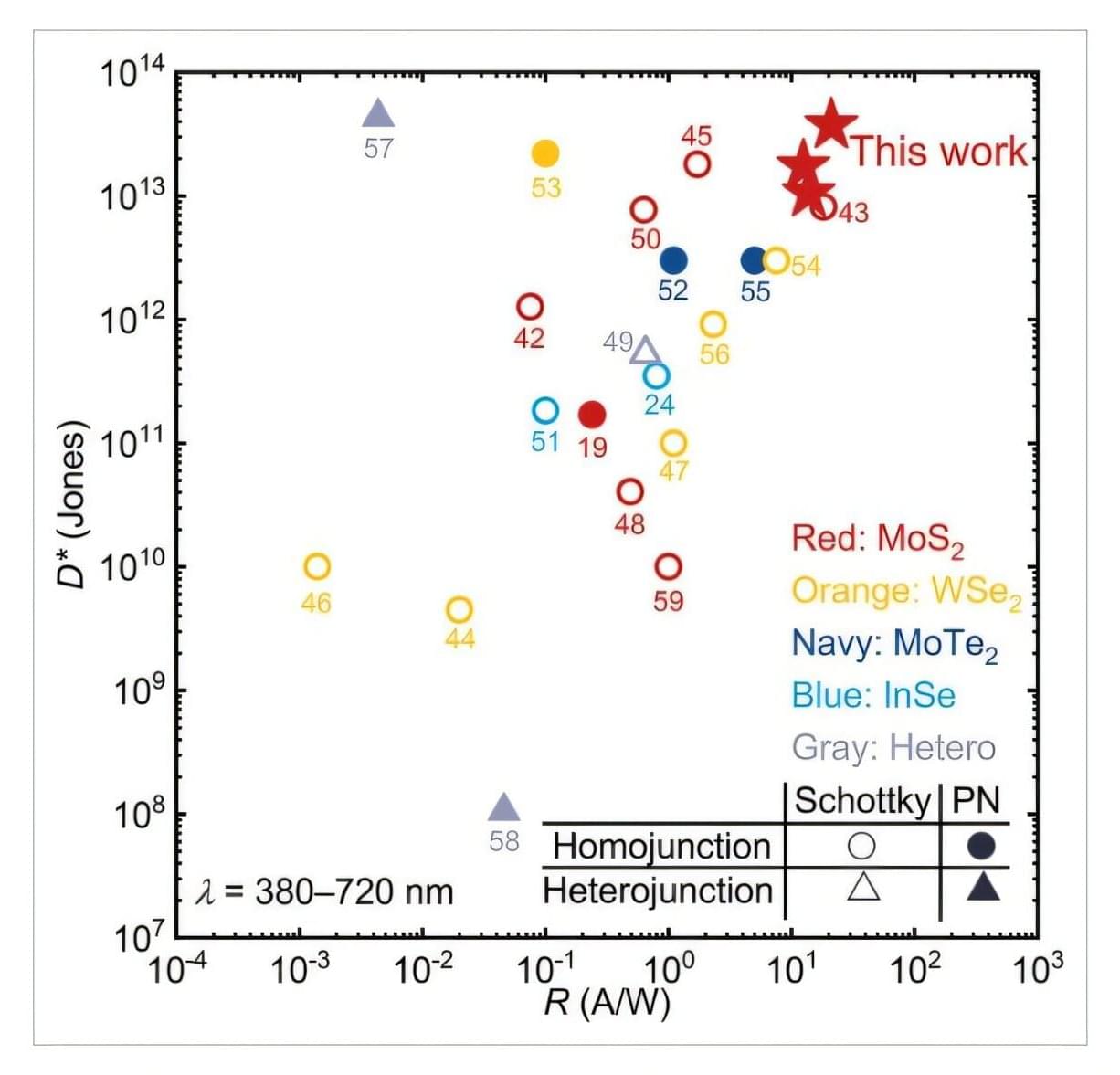

Silicon semiconductors used in existing photodetectors have low light responsivity, and the two-dimensional semiconductor MoS₂ (molybdenum disulfide) is so thin that doping processes to control its electrical properties are difficult, limiting the realization of high-performance photodetectors.

A KAIST research team has overcome this technical limitation and developed the world’s highest-performing self-powered photodetector, which operates without electricity in environments with a light source. This paves the way for precise sensing without batteries in wearable devices, biosignal monitoring, IoT devices, autonomous vehicles, and robots, as long as a light source is present.

Professor Kayoung Lee’s research team from the School of Electrical Engineering developed the self-powered photodetector, which demonstrated a sensitivity up to 20 times higher than existing products, marking the highest performance level among comparable technologies reported to date. The work is published in the journal Advanced Functional Materials.

Apple’s prioritization of shareholder value through massive share buybacks over investing in innovation and R&D may be a strategic misstep that could hinder its future success and allow competitors to gain an edge, particularly in emerging markets like AI

## Questions to inspire discussion.

Innovation and Investment.

🔬 Q: How could Apple’s buyback program have been used differently? A: A: Apple’s $700 billion share buyback over the past decade could have been invested in R&D to develop innovative products like a car, potentially yielding greater long-term value.

🤖 Q: What is Apple’s current stance on AI development? A: Apple’s inaction in AI is notable, with Siri’s performance declining over time, indicating a lack of focus on this crucial technology sector.

Product Development and Market Strategy.

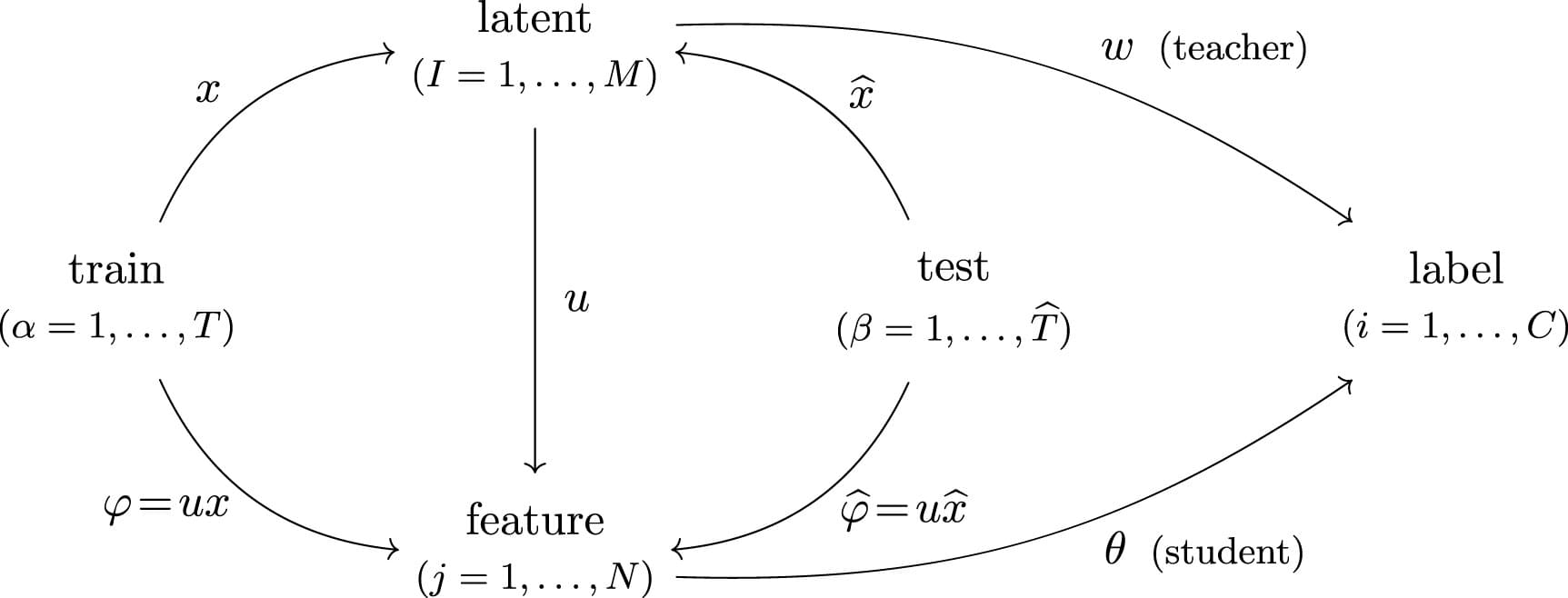

From self-driving cars to facial recognition, modern life is growing more dependent on machine learning, a type of artificial intelligence (AI) that learns from datasets without explicit programming.

Despite its omnipresence in society, we’re just beginning to understand the mechanisms driving the technology. In a recent study, Zhengkang (Kevin) Zhang, assistant professor in the University of Utah’s Department of Physics & Astronomy, demonstrated how physicists can play an important role in unraveling its mysteries.

“People used to say machine learning is a black box—you input a lot of data and at some point, it reasons and speaks and makes decisions like humans do. It feels like magic because we don’t really know how it works,” said Zhang. “Now that we’re using AI across many critical sectors of society, we have to understand what our machine learning models are really doing—why something works or why something doesn’t work.”

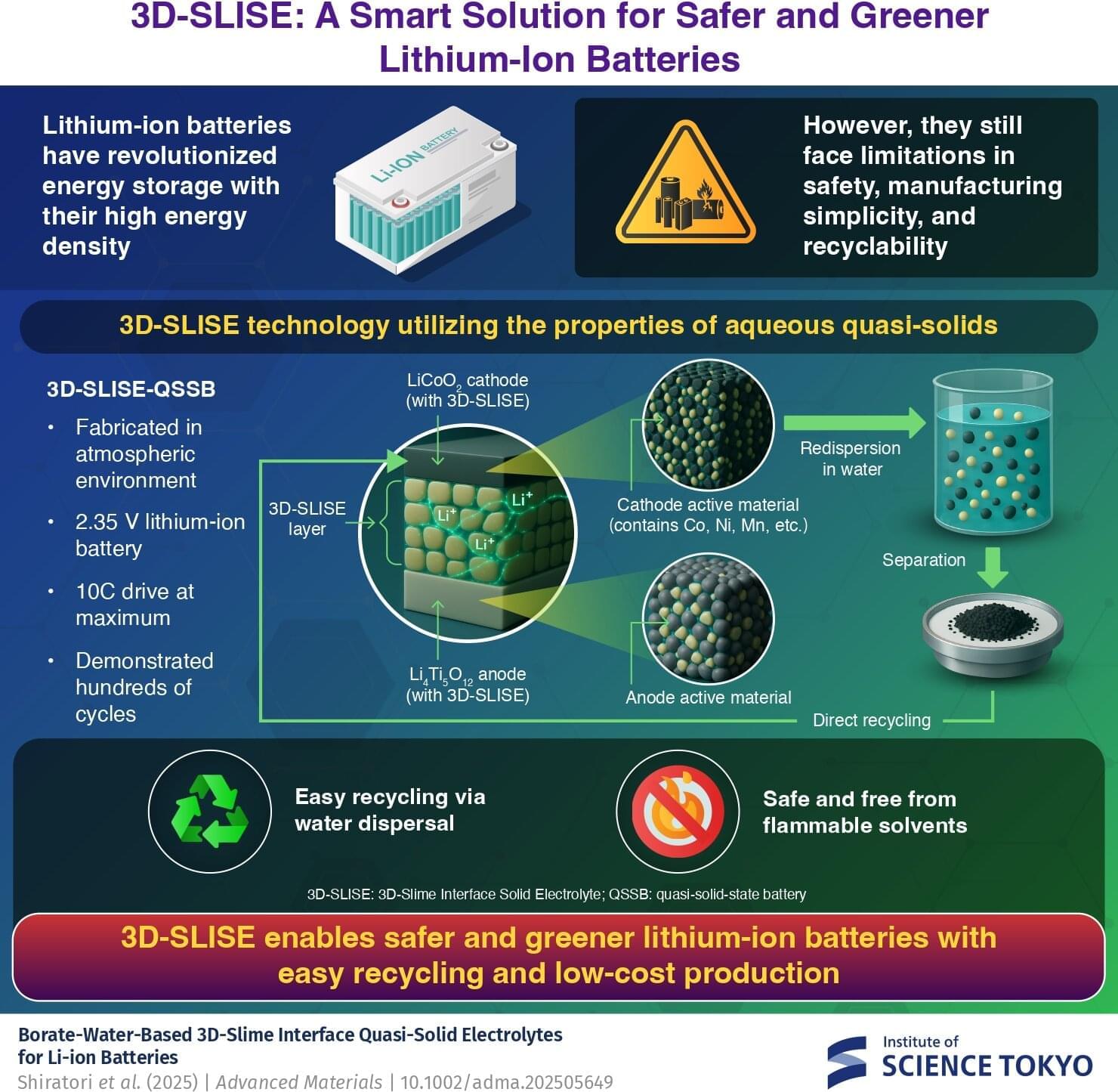

3D-SLISE is a quasi-solid electrolyte developed at the Institute of Science Tokyo, which enables safe, fast-charging/discharging of 2.35 V lithium-ion batteries to be fabricated under ambient conditions. With energy-efficient manufacturing using raw materials free from flammable organic solvents, the technique eliminates the need for dry rooms or high-temperature processing. Moreover, it also allows direct recovery of active materials through water dispersal—ensuring a sustainable, recyclable approach to battery production.

In today’s era of portable power and clean energy, lithium-ion batteries form the backbone of modern technology—powering everything from smartphones to electric vehicles. While demand for lithium-ion batteries continues to grow, so do concerns about their safety, environmental impact, and recyclability. Most lithium-ion batteries that rely on flammable organic solvents are energy-intensive to manufacture, and require complicated recycling processes. These issues not only drive up costs but also pose serious safety and environmental risks —highlighting the need for safer and cleaner alternatives.

To address this challenge, a research team from Institute of Science Tokyo (Science Tokyo), Japan, led by Specially Appointed Professor Yosuke Shiratori and Associate Professor Shintaro Yasui from the Zero-Carbon Energy Research Institute, Science Tokyo, developed a new quasi-solid electrolyte called 3D-Slime Interface Quasi-Solid Electrolyte (3D-SLISE), which can transform battery manufacturing. With a simple borate-water matrix, the electrolyte supports the production of 2.35 V lithium-ion batteries under standard air conditions. The detailed findings of the study were made available in the journal Advanced Materials on July 9, 2025.