With the surging popularity for electric vehicles (EVs), rapid charging is a challenge as it requires power delivery exceeding 1 MW (which can power about 1,000 homes). Conventional charging stations rely on bulky line frequency transformers (LFTs), which are expensive due to extensive use of copper and iron. These stations also have multiple conversion stages involving stepping up or down current, or converting AC to DC and vice versa. This can greatly increase cost and reduce efficiency.

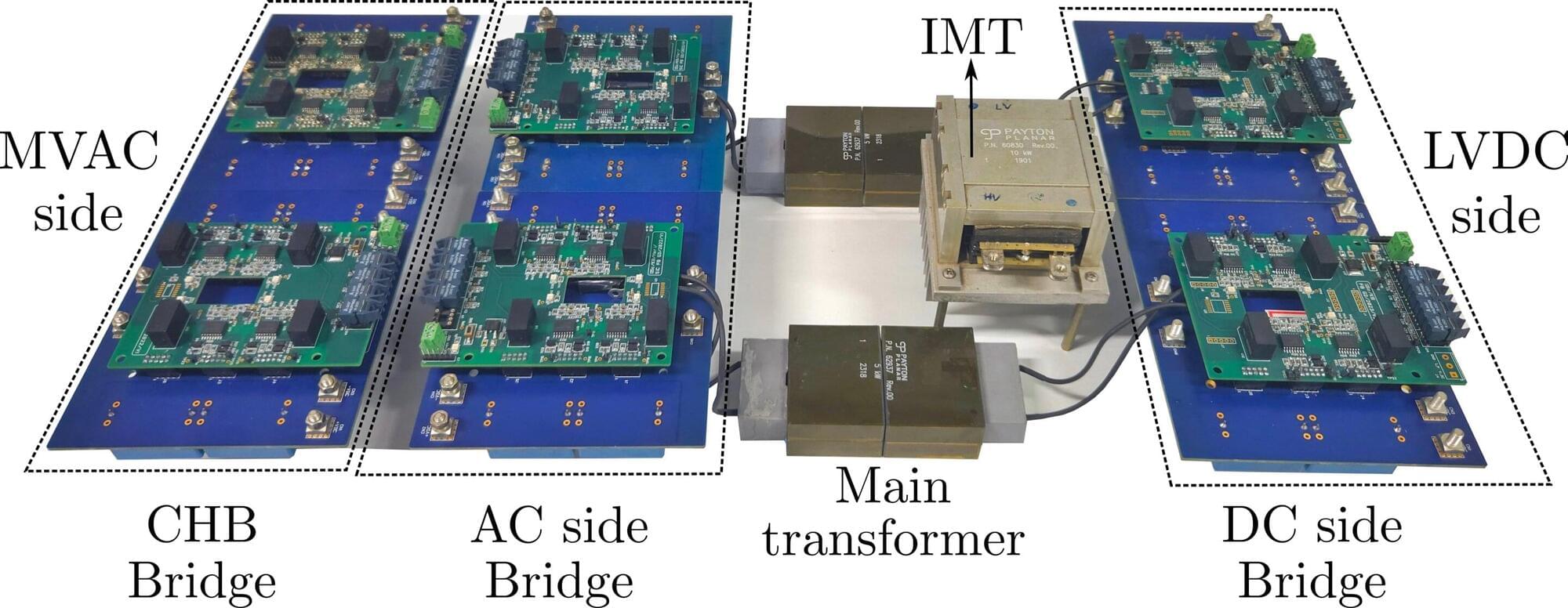

To solve this problem, researchers at the Department of Electrical Engineering (EE), Indian Institute of Science (IISc), in collaboration with Delta Electronics India, have developed a novel cascaded H-bridge (CHB)-based multiport DC converter that directly connects to the medium-voltage AC (MVAC) electricity grid. This eliminates the need for large and expensive LFTs.

Published in IEEE Transactions on Industrial Electronics, the study shows that such converters can help address the growing power demands of fast-charging EV stations, crucial for scaling up India’s EV infrastructure.