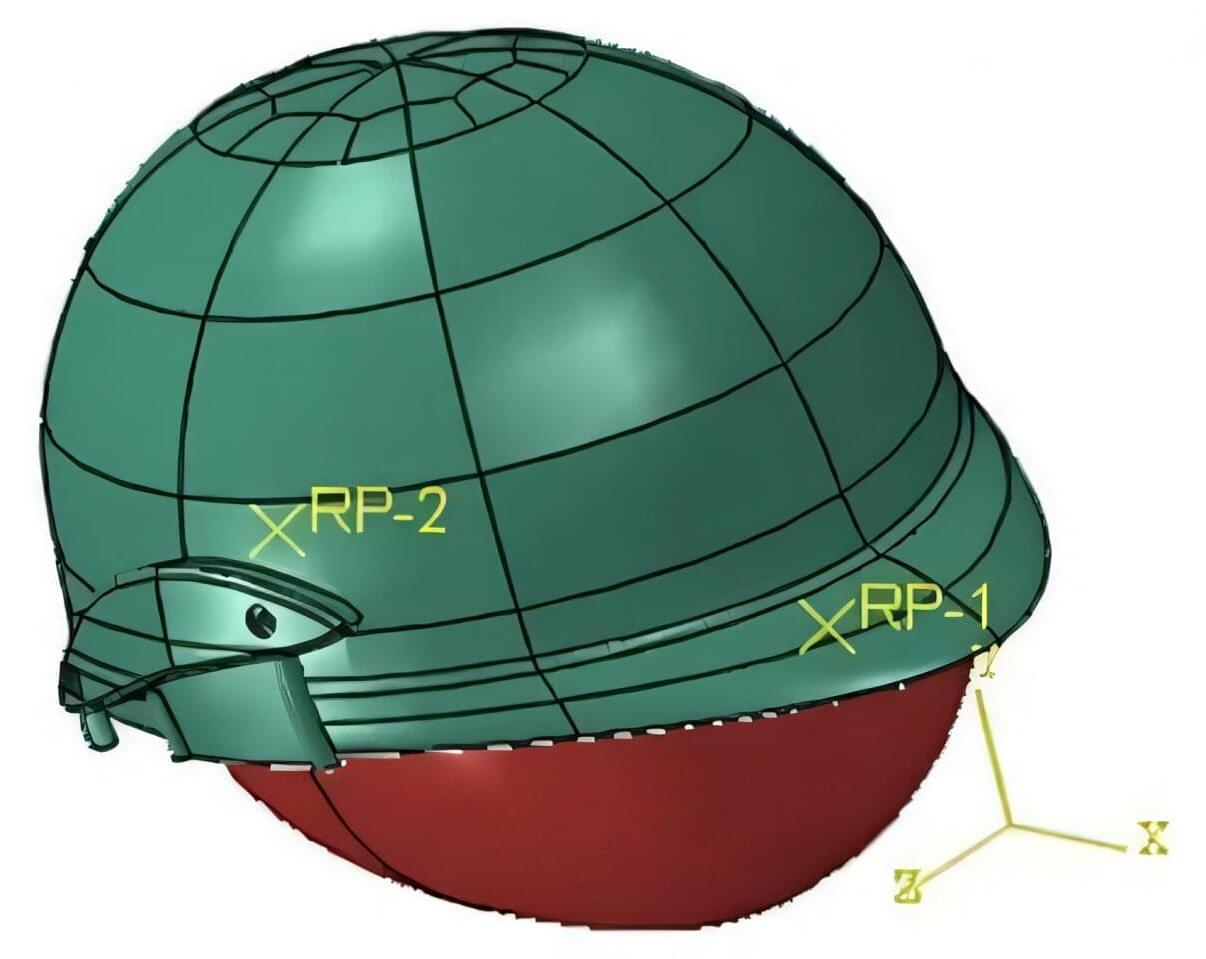

The researchers behind these findings uncovered the Infinity Galaxy while examining images from the JWST’s 255-hour treasury COSMOS-Web survey. In addition to the suspected direct collapse black hole that sits between the colliding galaxies, the team found that each nucleus of those galaxies also contains a supermassive black hole!

“Everything is unusual about this galaxy. Not only does it look very strange, but it also has this supermassive black hole that’s pulling a lot of material in,” team leader and Yale University researcher Pieter van Dokkum said in a statement. “The biggest surprise of all was that the black hole was not located inside either of the two nuclei but in the middle.

We asked ourselves: How can we make sense of this?