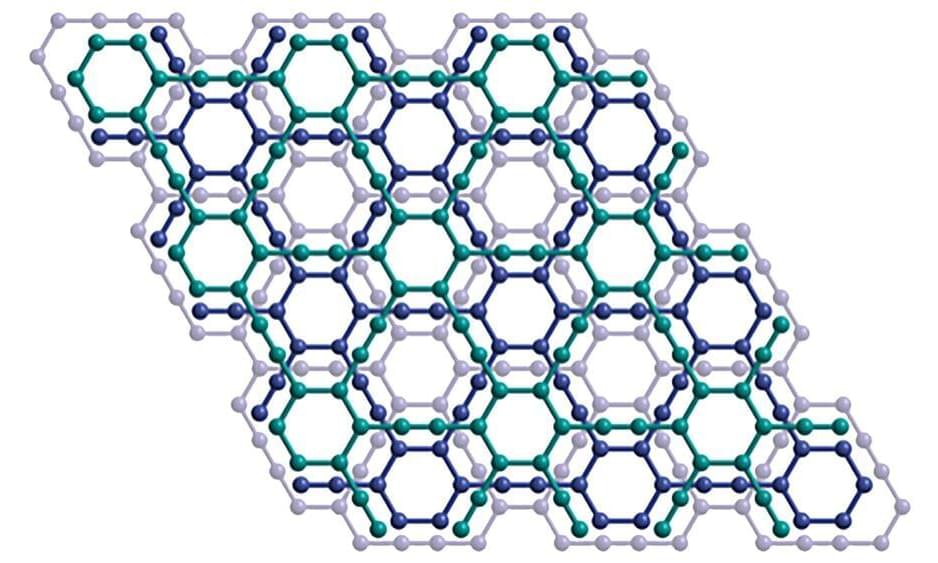

2D material synthesised from nanocluster fullerene for the first time.

An international team of researchers, led by scientists at the University of Manchester, has developed a fast and economical method of converting methane, or natural gas, into liquid methanol at ambient temperature and pressure. The method takes place under continuous flow over a photo-catalytic material using visible light to drive the conversion.

To help observe how the process works and how selective it is, the researchers used neutron scattering at the VISION instrument at Oak Ridge National Laboratory’s Spallation Neutron Source.

The method involves a continuous flow of methane/oxygen-saturated water over a novel metal-organic framework (MOF) catalyst. The MOF is porous and contains different components that each have a role in absorbing light, transferring electrons and activating and bringing together methane and oxygen. The liquid methanol is easily extracted from the water. Such a process has commonly been considered “a holy grail of catalysis” and is an area of focus for research supported by the U.S. Department of Energy. Details of the team’s findings, titled “Direct photo-oxidation of methane to methanol over a mono-iron hydroxyl site,” are published in Nature Materials.

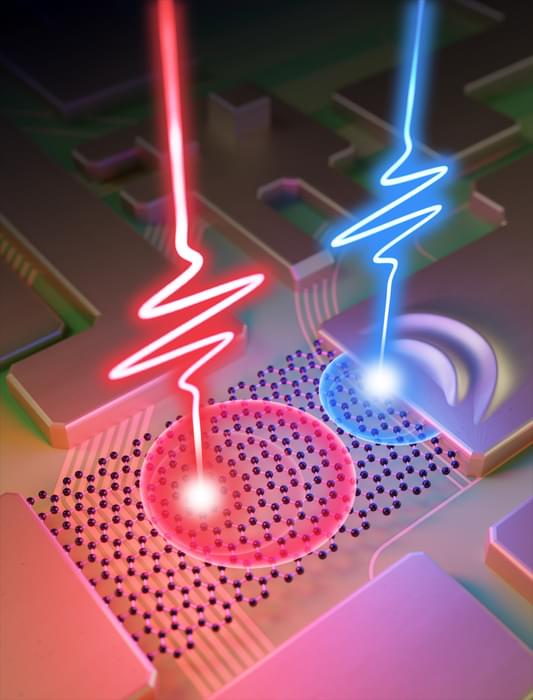

The first logic gate to operate at femtosecond timescales could help usher in an era of information processing at petahertz frequencies – a million times faster than today’s gigahertz-scale computers. The new gate, developed by researchers at the University of Rochester in the US and the Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) in Germany, is an application of lightwave electronics – essentially, shuffling electrons around with light fields – and harnesses both real and virtual charge carriers.

In lightwave electronics, scientists use laser light to guide the motion of electrons in matter, then exploit this control to create electronic circuit elements. “Since light oscillates so fast (roughly a few hundred million times per second), using light could speed up electronics by a factor of roughly 10 000 as compared to computer chips,” says Tobias Boolakee, a laser physicist in Peter Hommelhoff’s group at the FAU and the first author of a study in Nature on the new gate. “With our present work, we have been able propose the idea for a first light field-driven logic gate (the fundamental building block for any computer architecture) and also demonstrate its working principle experimentally.”

In the work, Boolakee and colleagues prepared tiny graphene-based wires connected to two gold electrodes and illuminated them with a laser pulse lasting a few tens of femtoseconds (10-15 s). This laser pulse excites, or sets in motion, the electrons in graphene and causes them to propagate in a particular direction – so generating a net electrical current.

“Blinking” behavior of fluorophores, being harmful for the majority of super-resolved techniques, turns into a key property for stochastic optical fluctuation imaging and its modifications, allowing one to look at the fluorophores already used in conventional microscopy, such as graphene quantum dots, from a completely new perspective. Here we discuss fluorescence of aggregated ensembles of graphene quantum dots structured at submicron scale. We study temperature dependence and stochastic character of emission. We show that considered quantum dots ensembles demonstrate rather complicated temperature-dependent intermittent emission, that is, “blinking” with a tendency to shorten “blinking” times with the increase of temperature.

A 30-year-old Kenyan engineer named Nzambi Matee has come up with a promising way to upcycle plastic trash that would’ve otherwise landed in landfills — by pressing it, with the addition of sand, into sturdy bricks and paving stones.

Her Nairobi-based company, Gjenge Makers, produces a variety of different paving stones, which are already being put to use to line sidewalks, driveways, and roads.

According to the engineer, the plastic pavers are seven times stronger, 15 percent cheaper to produce and lighter than concrete. And the venture is just getting started, with the company now investigating ways to construct affordable housing from similar materials.

Get a year of Nebula and Curiosity Stream for only $14.79 when you sign up at http://www.curiositystream.com/joescott.

We’ve been hearing about the potential of graphene for decades, and yet very few of the big promises have come to pass. But a new aluminum graphene battery design is coming out this year that could charge a phone in less than a minute, and it may be the future of energy storage.

Want to support the channel? Here’s how:

Patreon: http://www.patreon.com/answerswithjoe.

Channel Memberships: https://www.youtube.com/channel/UC-2YHgc363EdcusLIBbgxzg/join.

T-Shirts & Merch: http://www.answerswithjoe.com/store.

Check out my 2nd channel, Joe Scott TMI:

https://www.youtube.com/channel/UCqi721JsXlf0wq3Z_cNA_Ew.

And my podcast channel, Conversations With Joe:

https://www.youtube.com/channel/UCJzc7TiJ2nnuyJkUpOZ8RKA

You can listen to my podcast, Conversations With Joe on Spotify, Apple Podcasts, Google Podcasts, or wherever you get your podcasts.