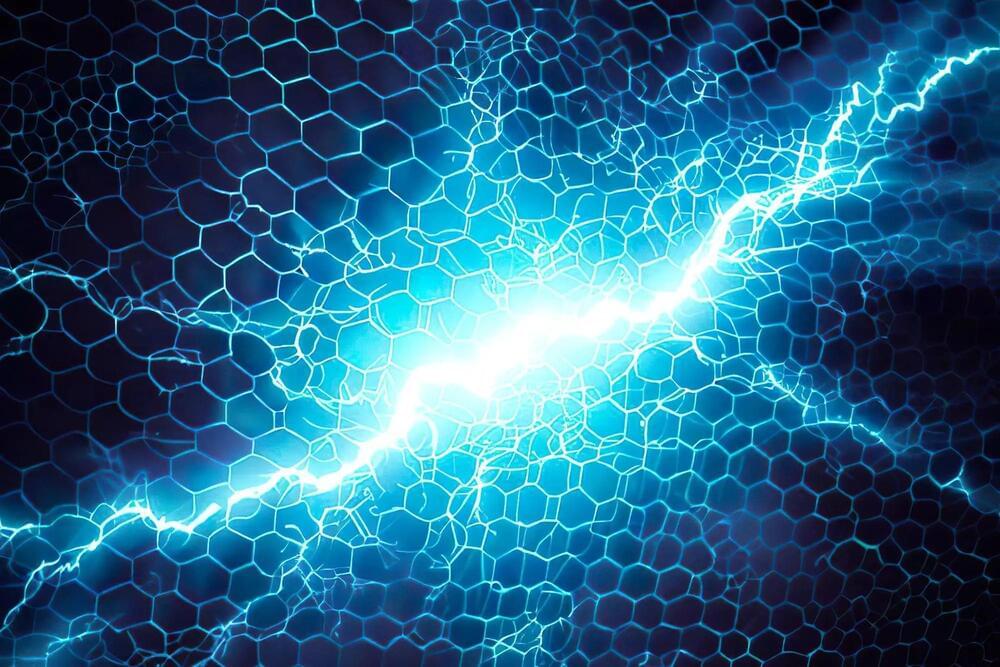

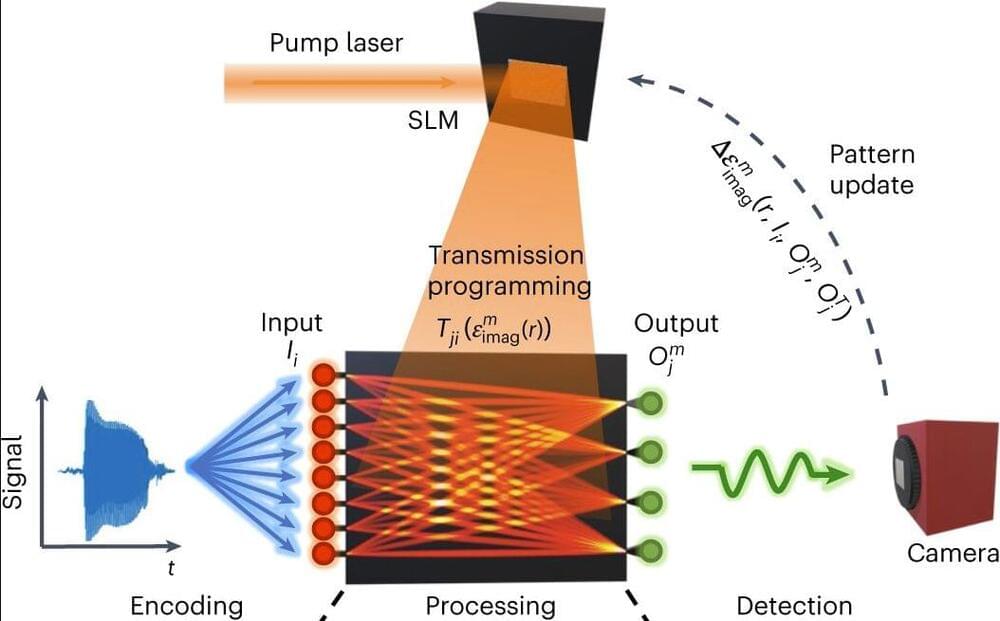

Overlapping lattices and innovative techniques have unlocked the secrets of bosonic materials, opening doors to unprecedented possibilities in condensed matter physics.

Physicists at UC Santa Barbara have unlocked the secrets of an extraordinary material made of bosons. Traditionally, the scientific community has focused on understanding the behavior of fermions, the subatomic particles responsible for the stability and interaction of matter. However, this recent breakthrough explores the unique properties of bosons, shedding light on a less explored realm of particle physics.

By overlapping lattices of tungsten diselenide and tungsten disulfide in a twisted configuration known as a moiré… More.

Sakkmesterke/iStock.