Fuzziness may rule the quantum realm, but it can be manipulated to our advantage.

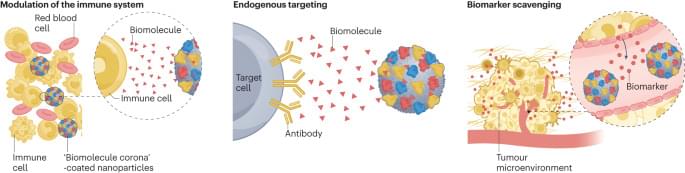

Nanoparticles (NPs) administered in the human body will undergo rapid surface modification upon contact with biological fluids driven by their interfacial interaction with a diverse range of biomolecules. Such spontaneous self-assembly and adsorption of proteins and other biomolecules onto the NP surface constitute what is commonly known as the protein or biomolecule corona. This surface biotransformation of the NPs modulates their biological interactions and impact on physiological systems and can influence their overall pharmacological profile. Here, we comment on how the initially considered ‘nuisance’ of the in vivo corona formation can now be considered a nanoparticle engineering tool for biomedical use, such as in endogenous tissue targeting, personalized biomarker discovery and immunomodulation.

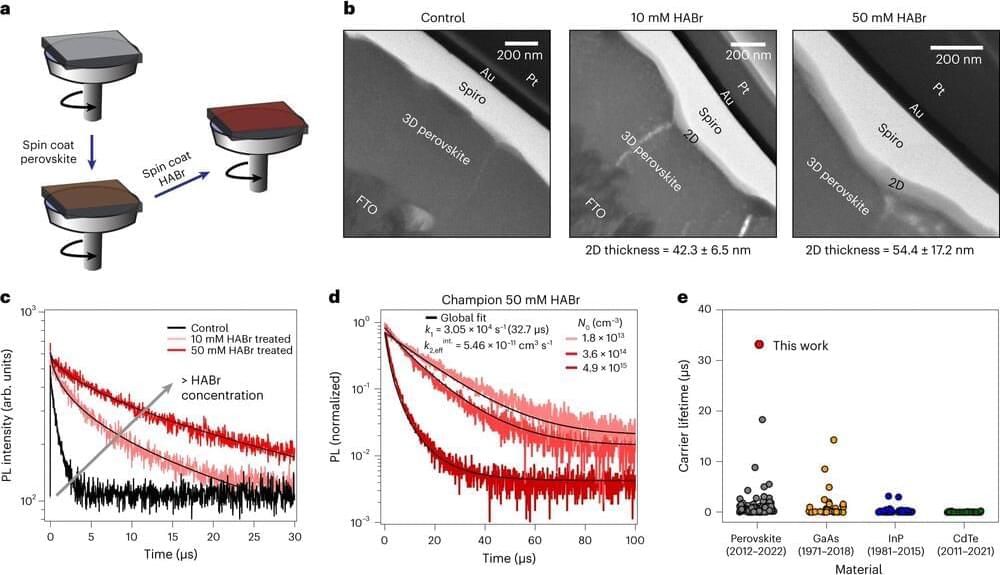

Perovskites, a broad class of compounds with a particular kind of crystal structure, have long been seen as a promising alternative or supplement to today’s silicon or cadmium telluride solar panels. They could be far more lightweight and inexpensive, and could be coated onto virtually any substrate, including paper or flexible plastic that could be rolled up for easy transport.

In their efficiency at converting sunlight to electricity, perovskites are becoming comparable to silicon, whose manufacture still requires long, complex, and energy-intensive processes. One big remaining drawback is longevity: They tend to break down in a matter of months to years, while silicon solar panels can last more than two decades. And their efficiency over large module areas still lags behind silicon.

Now, a team of researchers at MIT and several other institutions has revealed ways to optimize efficiency and better control degradation, by engineering the nanoscale structure of perovskite devices.

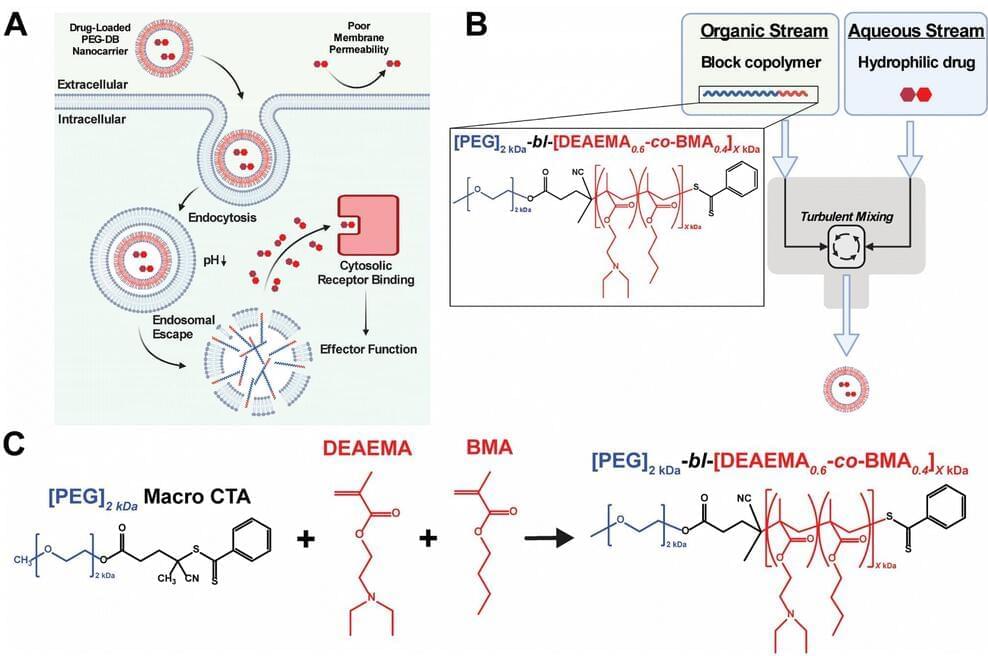

Vanderbilt researchers have developed a new nanoparticle that can more get drugs inside cells to boost the immune system and fight diseases such as cancer.

The research is led by John Wilson, associate professor of chemical and biomolecular engineering and biomedical engineering, as well as a corresponding author on the paper about the research that was recently published in the journal Nanoscale.

Wilson, who is Principal Investigator of the Immunoengineering Lab at Vanderbilt and a Chancellor Faculty Fellow, and his team created a polymeric nanoparticle that can penetrate cell membranes and get drugs into the cytosol—or liquid—inside cells.

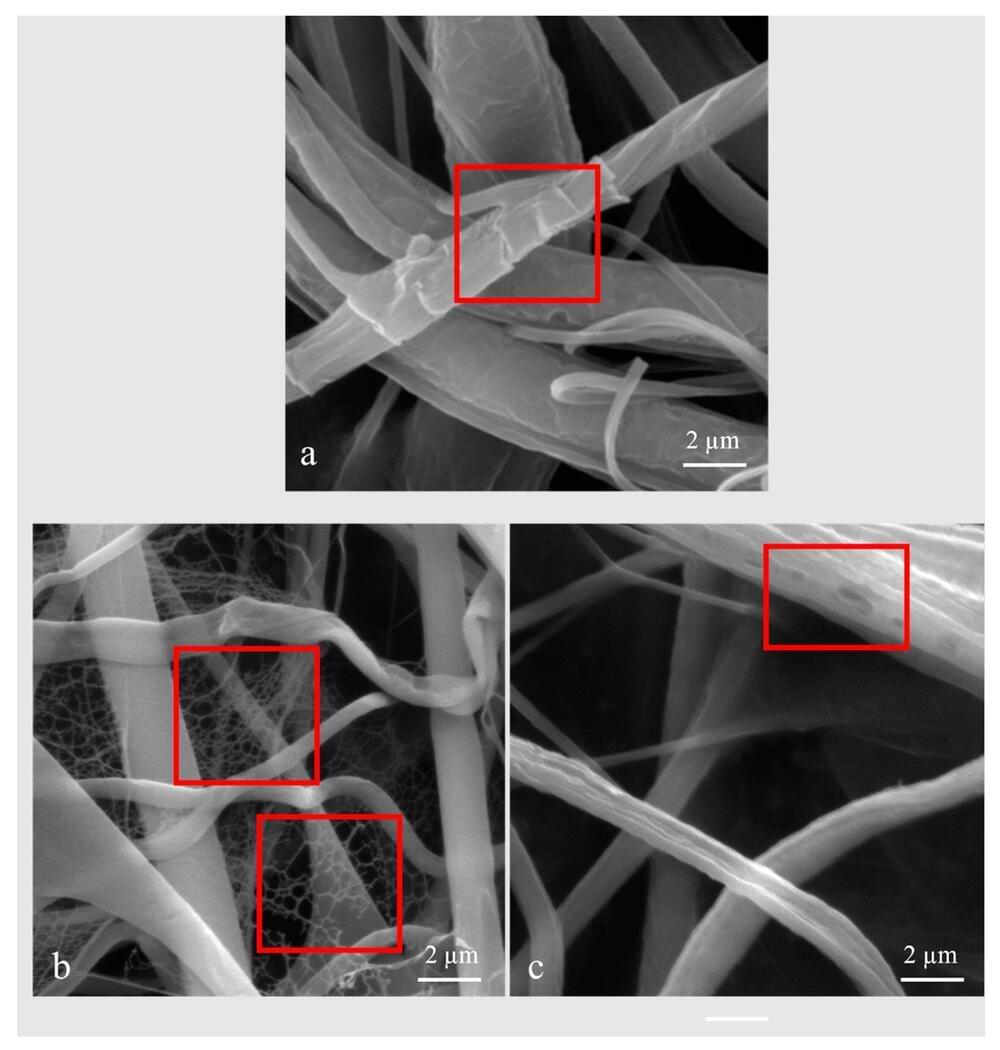

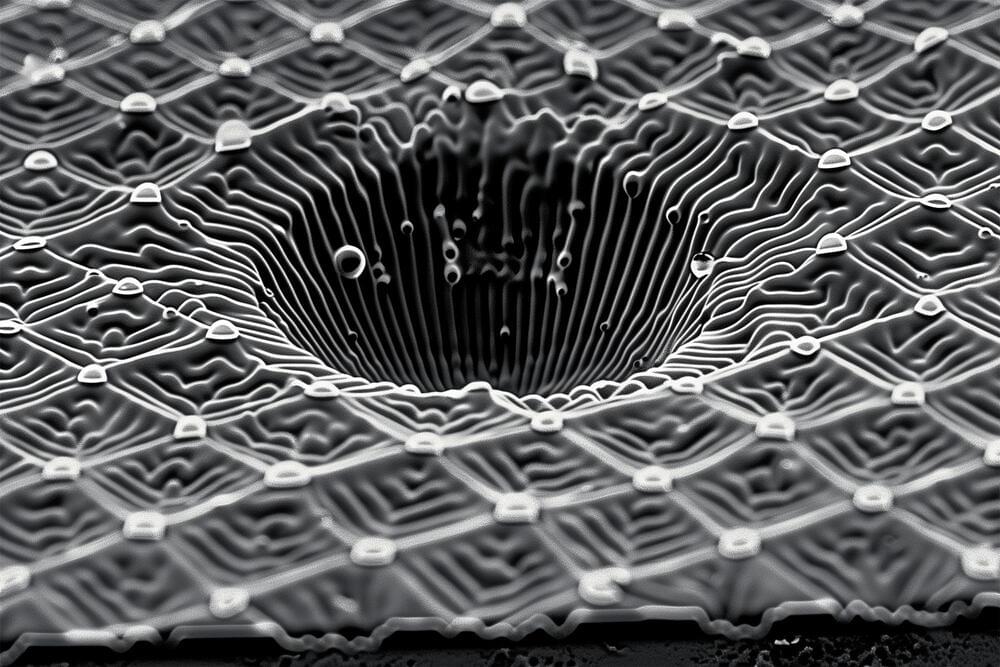

A new technique for electrospinning sponges has allowed scientists from the University of Surrey to directly produce 3D scaffolds—on which skin grafts could be grown from the patient’s own skin.

Electrospinning is a technique that electrifies droplets of liquid to form fibers from plastics. Previously, scientists had only been able to make 2D films. This is the first time anybody has electro-spun a 3D structure directly and on-demand so that it can be produced to scale. The research is published in the journal Nanomaterials.

Chloe Howard, from Surrey’s School of Computer Science and Electronic Engineering, said, After spinning these scaffolds, we grew skin cells on them. Seven days later, they were twice as viable as cells grown on 2D films or mats. They even did better than cells grown on plasma-treated polystyrene—previously, the gold standard. They were very happy cells on our 3D scaffolds.

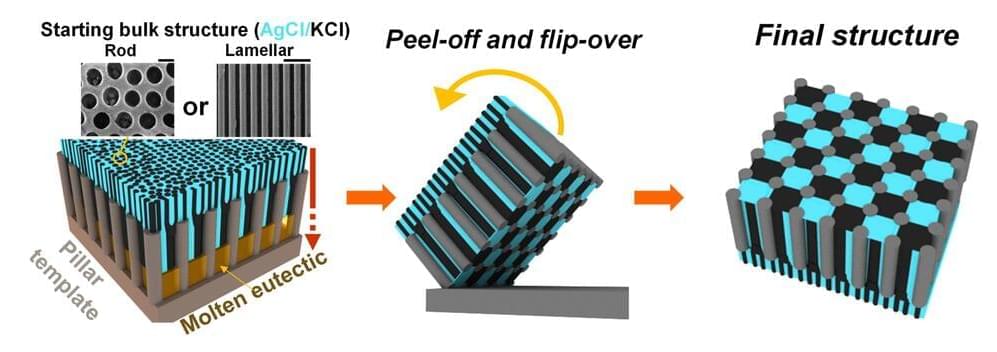

Self-assembled solidifying eutectic materials directed by a template with miniature features demonstrate unique microstructures and patterns as a result of diffusion and thermal gradients caused by the template. Despite the template trying to force the material to solidify into a regular pattern, when the template carries a lot of heat it also can interfere with the solidification process and cause disorder in the long-range pattern.

Researchers at the University of Illinois Urbana-Champaign and the University of Michigan Ann Arbor have developed a template material that carries almost no heat and therefore stops heat transfer between the template material itself and the solidifying eutectic material. They accomplished this by forming the template from a material with very low thermal conductivity, ultimately resulting in highly organized self-assembled microstructures.

The results of this research were recently published in the journal Advanced Materials.

High-speed experiments can help identify lightweight, protective “metamaterials” for spacecraft, vehicles, helmets, or other objects.

An intricate, honeycomb-like structure of struts and beams could withstand a supersonic impact better than a solid slab of the same material. What’s more, the specific structure matters, with some being more resilient to impacts than others.

That’s what MIT engineers are finding in experiments with microscopic metamaterials — materials that are intentionally printed, assembled, or otherwise engineered with microscopic architectures that give the overall material exceptional properties.

SpaceX recently tested Starlink’s Direct to Cell satellites and posted on Elon Musk’s X platform.

The test X post simply said: “This post was sent through a SpaceX Direct to Cell satellite.”

SpaceX’s Director of Satellite Engineering provided more information about the X post. He revealed that the post was made under the cover of trees in a small valley in the Santa Cruz Mountains.

Varda plans to pioneer the use of orbital manufacturing spacecraft such as this capsule to open unique pathways for engineering materials in space. “Processing materials in microgravity, or the near-weightless conditions found in space, offers a unique environment not available through terrestrial processing,” the company’s website states.

Related: Private Varda Space capsule returns to Earth with space-grown antiviral drug aboard

The recovery made Varda only the third private company to recover an intact spacecraft from orbit, after SpaceX and Boeing.

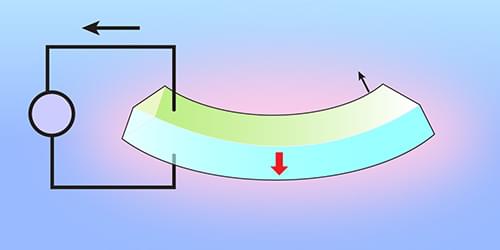

The engineering of structural deformations in light-sensitive semiconductors can boost the efficiency of solar cells.

The quest for an efficient method to convert solar energy into electricity is crucial in the pursuit of carbon neutrality and environmental sustainability. Traditional solar cells are based on junctions between semiconductors, where a current is produced by photogenerated carriers separated by an electric field at the junction. Efforts to enhance solar-cell performance have focused on refining semiconductor properties and on perfecting devices. Concurrently, researchers are exploring alternative photovoltaic mechanisms that could work in synergy with the junction-based photovoltaic effect to boost solar-cell efficiency. Within this context, the engineering of a strain gradient in the material has emerged as a promising research direction. In this phenomenon, known as the flexophotovoltaic effect, an inhomogeneous strain in the material produces a photovoltaic effect in the absence of a junction [1].