Art and science combine in this engineering course to let students turn their brainwaves into creative works.

Ceramic nanowires could essentially be used even for car tires reducing even hazardous rubber waste.

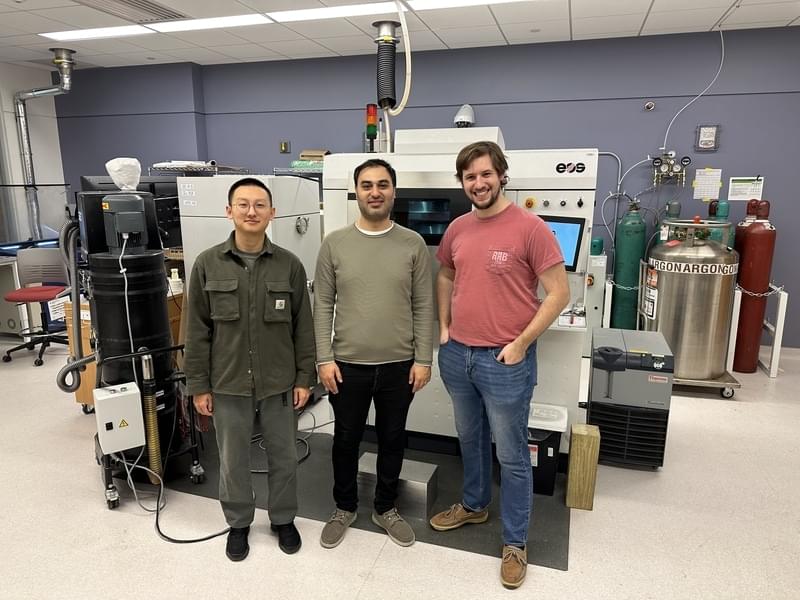

A team of MIT-led engineers found a simple, inexpensive way to strengthen Inconel 718 with ceramic nanowires to be used in metal PBF AM processes. The team believes that their general approach could be used to improve many other materials. “There is always a significant need for the development of more capable materials for extreme environments. We believe that this method has great potential for other materials in the future,” said Ju Li, the Battelle Energy Alliance Professor in Nuclear Engineering and a professor in MIT’s Department of Materials Science and Engineering (DMSE).

Li, who is also affiliated with the Materials Research Laboratory (MRL), is one of three corresponding authors of a paper on the work that appeared in the April 5 issue of Additive Manufacturing. The other corresponding authors are Professor Wen Chen of the University of Massachusetts at Amherst and Professor A. John Hart of the MIT Department of Mechanical Engineering.

Co-first authors of the paper are Emre Tekoğlu, an MIT postdoc in the Department of Nuclear Science and Engineering (NSE); Alexander D. O’Brien, an NSE graduate student; and Jian Liu of UMass Amherst. Additional authors are Baoming Wang, an MIT postdoc in DMSE; Sina Kavak of Istanbul Technical University; Yong Zhang, a research specialist at the MRL; So Yeon Kim, a DMSE graduate student; Shitong Wang, an NSE graduate student; and Duygu Agaogullari of Istanbul Technical University. The study was supported by Eni S.p. A. through the MIT Energy Initiative, the National Science Foundation, and ARPA-E.

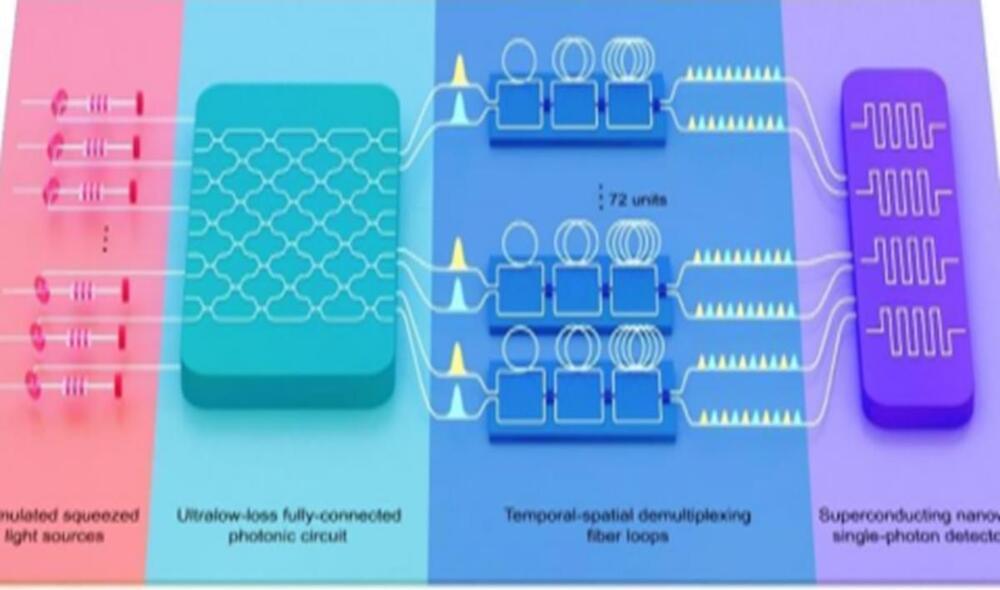

With the successful development of the Jiuzhang 3.0 quantum computer prototype, which makes use of 255 detected photons, China continues to hold a world-leading position in the field of quantum computer research and development, lead scientists for the program told the Global Times on Wednesday.

The research team, composed of renowned quantum physicists Pan Jianwei and Lu Chaoyang from the University of Science and Technology of China in collaboration with the Shanghai Institute of Microsystem and Information Technology under the Chinese Academy of Sciences and the National Parallel Computer Engineering Technology Research Center, announced the successful construction of a 255-photon-based prototype quantum computer named Jiuzhang 3.0 early Wednesday morning.

The quantum computing feat accomplished by the team of talents achieves a speed that is 10 quadrillion times faster in solving Gaussian boson sampling (GBS) problems compared with the world’s fastest supercomputers.

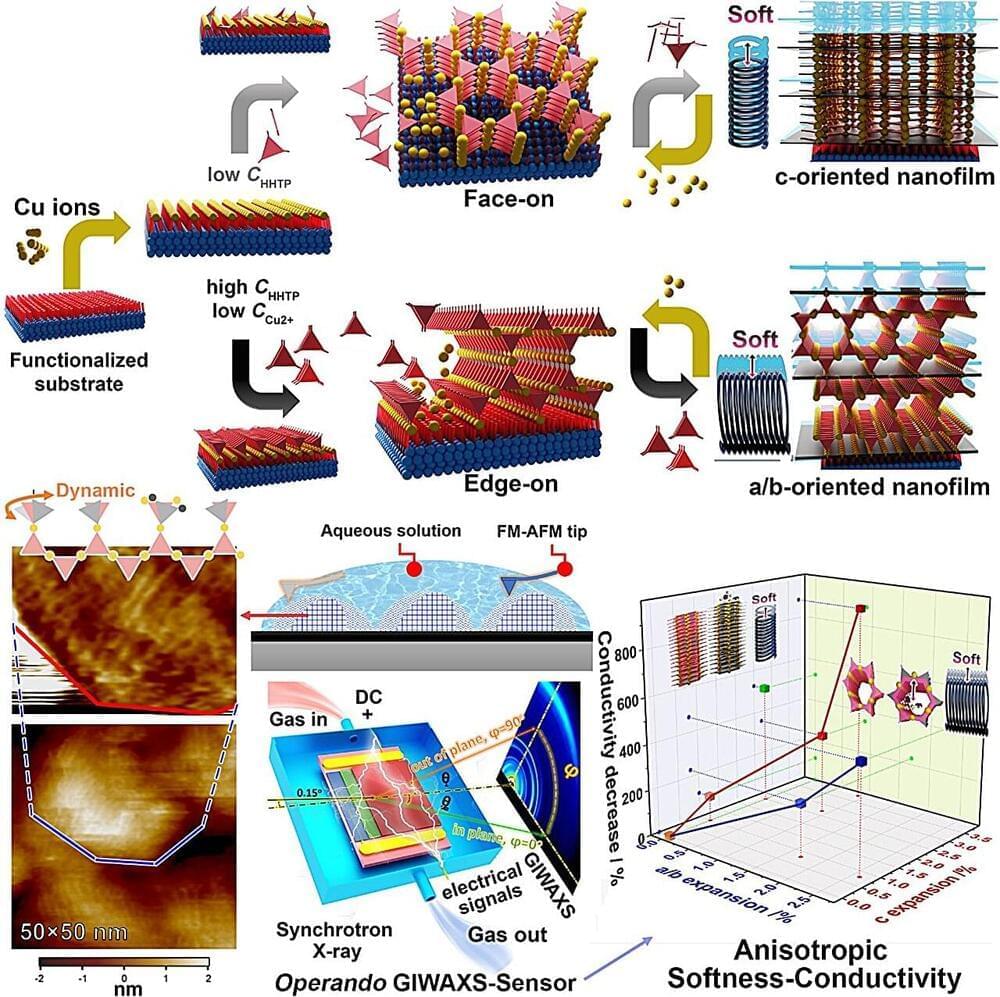

Researchers from the Institute of Process Engineering (IPE) of the Chinese Academy of Sciences and Kyoto University have proposed a strategy to grow “face-on” and “edge-on” conductive metal-organic frameworks (cMOF) nanofilms on substrates by controlling the “stand-up” behaviors of ligands on various surfaces to overcome the difficulty in the orientation control of such films.

They established operando characterization methodology using atomic force microscopy and X-ray to demonstrate the softness of the crystalline nanofilms and reveal their unique conductive functions. The study was published in Proceedings of the National Academy of Sciences on Sept. 25.

CMOFs have great potential for use in modern electrical devices due to their porous nature and the ability to conduct charges in a regular network. cMOFs applied in electrical devices normally hybridize with other materials, especially substrates. Therefore, precisely controlling the interface between a cMOF and a substrate is crucial.

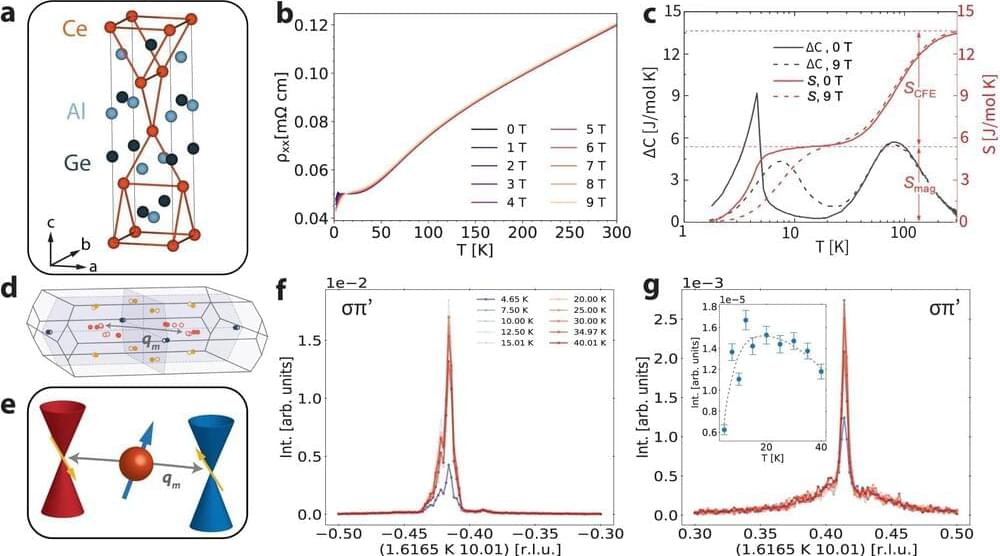

Researchers who have been working for years to understand electron arrangement and magnetism in certain semimetals have been frustrated by the fact that the materials only display magnetic properties if they are cooled to just a few degrees above absolute zero.

A new MIT study led by Mingda Li, associate professor of nuclear science and engineering, and co-authored by Nathan Drucker, a graduate research assistant in MIT’s Quantum Measurement Group and Ph.D. student in applied physics at Harvard University, along with Thanh Nguyen and Phum Siriviboon, MIT graduate students working in the Quantum Measurement Group, is challenging that conventional wisdom.

The open-access research, published in Nature Communications, for the first time shows evidence that topology can stabilize magnetic ordering, even well above the magnetic transition temperature—the point at which magnetism normally breaks down.

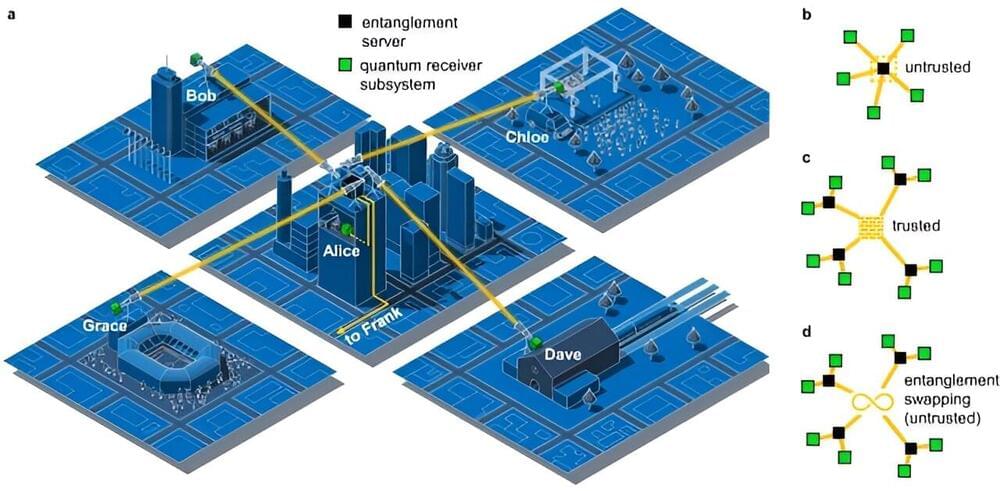

Quantum communications have rapidly progressed toward practical, large-scale networks based on quantum key distributions that spearhead the process. Quantum key distribution systems typically include a sender “Alice,” a receiver “Bob,” who generate a shared secret from quantum measurements for secure communication. Although fiber-based systems are well-suited for metropolitan scale, a suitable fiber infrastructure might not always be in place.

In a new report in npj Quantum Information, Andrej Kržič and a team of scientists developed an entanglement-based, free-space quantum network. The platform offered a practical and efficient alternative for metropolitan applications. The team introduced a free-space quantum key distribution system to demonstrate its use in realistic applications in anticipation of the work to establish free-space networks as a viable solution for metropolitan applications in the future global quantum internet.

Quantum communication typically aims to distribute quantum information between two or more parties. A series of revolutionary applications of quantum networks have provided a roadmap towards engineering a full-blown quantum internet. The proposed invention provides a heterogeneous network of special purpose sub-networks with diverse links and interconnects. The concept of quantum key distribution networks have driven this development to pave the way for other distributed quantum information processing methods to benchmark the technological maturity of quantum networks in general.

Wind turbines are a feat of engineering. The massive structures are visually impressive and generate vast amounts of clean energy via a natural and pollution-free source.

Because of that, you’d think they take a long time to install — especially when placed far out at sea.

However, at an offshore wind farm in Zhangpu, China, the state-owned China Three Gorges power company managed to get one up and running in just over a day, Electrek reports.

#evolution.

Promptbreeder is a self-improving self-referential system for automated prompt engineering. Give it a task description and a dataset, and it will automatically come up with appropriate prompts for the task. This is achieved by an evolutionary algorithm where not only the prompts, but also the mutation-prompts are improved over time in a population-based, diversity-focused approach.

OUTLINE:

0:00 — Introduction.

2:10 — From manual to automated prompt engineering.

10:40 — How does Promptbreeder work?

21:30 — Mutation operators.

36:00 — Experimental Results.

38:05 — A walk through the appendix.

Paper: https://arxiv.org/abs/2309.

Abstract:

Popular prompt strategies like Chain-of-Thought Prompting can dramatically improve the reasoning abilities of Large Language Models (LLMs) in various domains. However, such hand-crafted prompt-strategies are often sub-optimal. In this paper, we present Promptbreeder, a general-purpose self-referential self-improvement mechanism that evolves and adapts prompts for a given domain. Driven by an LLM, Promptbreeder mutates a population of task-prompts, and subsequently evaluates them for fitness on a training set. Crucially, the mutation of these task-prompts is governed by mutation-prompts that the LLM generates and improves throughout evolution in a self-referential way. That is, Promptbreeder is not just improving task-prompts, but it is also improving the mutationprompts that improve these task-prompts. Promptbreeder outperforms state-of-the-art prompt strategies such as Chain-of-Thought and Plan-and-Solve Prompting on commonly used arithmetic and commonsense reasoning benchmarks. Furthermore, Promptbreeder is able to evolve intricate task-prompts for the challenging problem of hate speech classification.

Authors: Chrisantha Fernando, Dylan Banarse, Henryk Michalewski, Simon Osindero, Tim Rocktäschel.

Lightweight materials with super strength and toughness are highly sought after. Spider silk, a sustainable material, meets these requirements but faces challenges in commercialization due to scientific understanding of its spinning mechanism, technical complexities in the process, and engineering hurdles in low-cost mass production. Here, drawing inspiration from nylon and Kevlar, we propose a theory on the nature of toughness and strength, unveiling the basic structure of silk fibers. Using these theories, we successfully produce the first “localized” full-length spider silk fiber via transgenic silkworms, showcasing high tensile strength (1,299 MPa) and exceptional toughness (319 MJ/m3). This breakthrough overcomes scientific, technical, and engineering obstacles, paving the way for spider silk’s commercialization as a sustainable substitute for synthetic fibers. Moreover, our theories provide essential guidance for developing super materials.

Developing sustainable materials with high strength and ultra-toughness is vital for ecological civilization. Using transgenic silkworms, we have successfully produced the first full-length spider silk, overcoming the scientific challenge of understanding the essence of toughness and strength. The resulting bionic spider silk exhibits high strength (1,299 MPa) and ultra-toughness (319 MJ/m3), offering a potentially sustainable substitute for synthetic commercial fibers. This breakthrough provides valuable insights for the development of super materials, including those for a space elevator, driving the advancement of civilization.