Researcher are now looking to make the most of this new discovery.

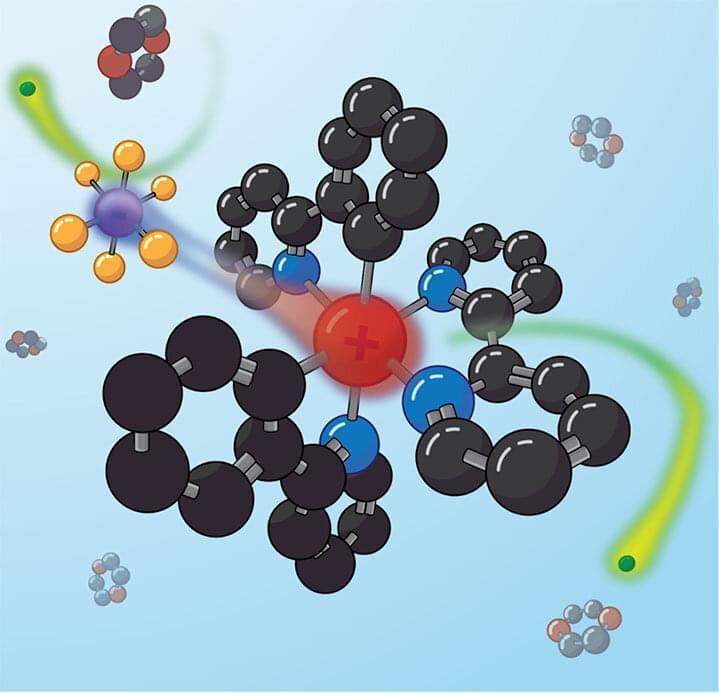

Did you know that bacteria in the natural world breathe by exhaling excess electrons, causing an intrinsic electrical grid? In a new study, Yale University researchers discovered that light could supercharge this electronic activity within biofilm bacteria, yielding an up to a 100-fold increase in electrical conductivity, according to a press release published by the institution earlier this month.

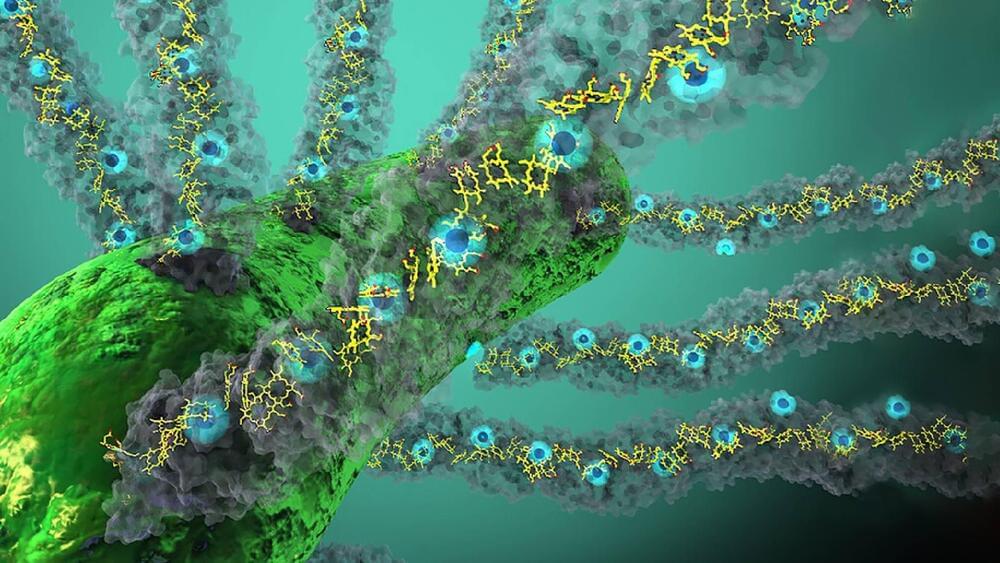

Yale researchers have found that bacteria buried underground have developed a way to respire by “breathing minerals” through tiny protein filaments called nanowires. This process can be amplified by light producing electricity.