Carbon nanotubes (CNTs) are considered ideal electrochemical energy storage materials due to their high electrical conductivity, large theoretical surface area, and good chemical stability.

However, CNTs tend to aggregate due to strong van der Waals forces, which reduces their electrochemically active area. This problem is even worse for single-walled carbon nanotubes (SWNTs) due to their high length-to-diameter ratio.

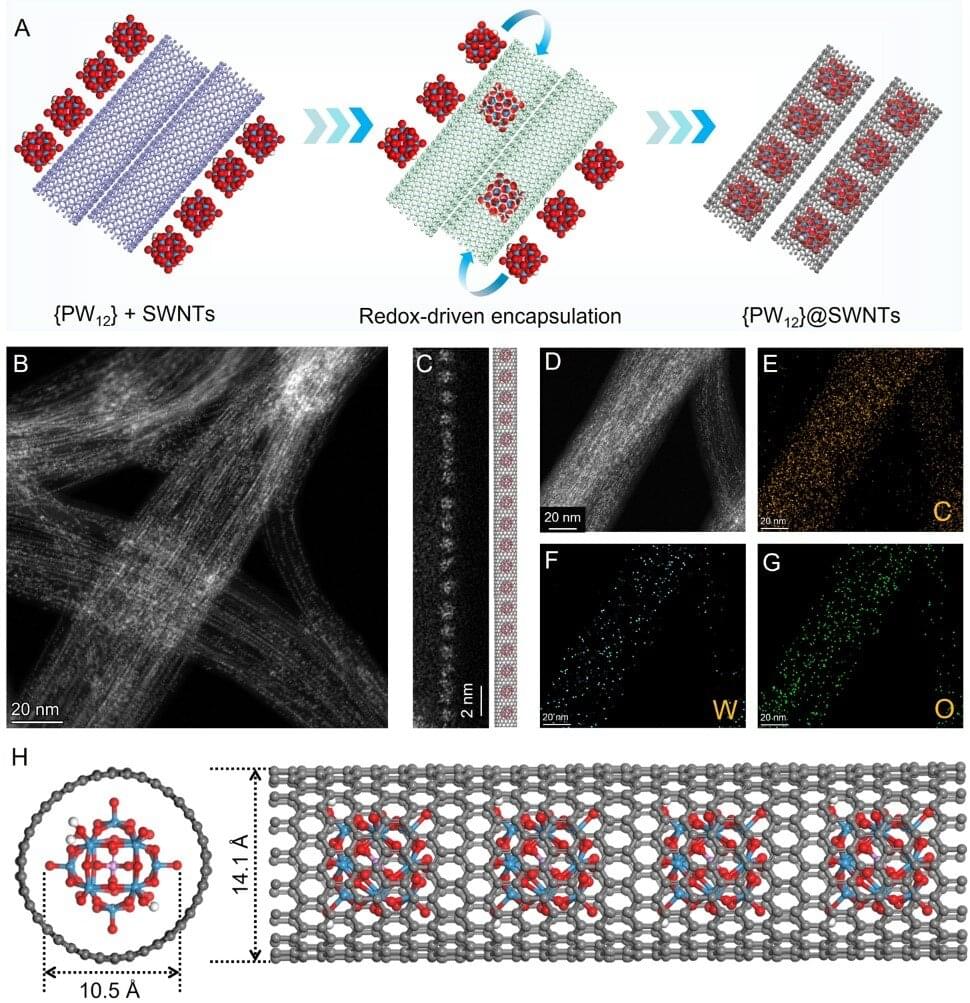

Recently, a joint research team led by Dr. Wang Xiao from the Shenzhen Institute of Advanced Technology (SIAT) of the Chinese Academy of Sciences, Dr. Zhu Sheng from Shanxi University, and Prof. Li Yan from Peking University has encapsulated polyoxometalate guest molecules within SWNTs (with a diameter of approximately 1.4 nm) to enhance the electrochemical energy storage of CNTs.