Substance that transforms into a conductive polymer using the body’s own chemistry could improve implantable electronics.

Summary: A newly developed sensor tracks a person’s vocal use and alerts them to overuse before vocal fatigue and potential injury occur.

Source: Northwestern University.

Northwestern University researchers have developed the first smart wearable device to continuously track how much people use their voices, alerting them to overuse before vocal fatigue and potential injury set in.

Scientists investigate an underwater alien orb in this costly adaptation of Michael Crichton’s 1987 bestseller.

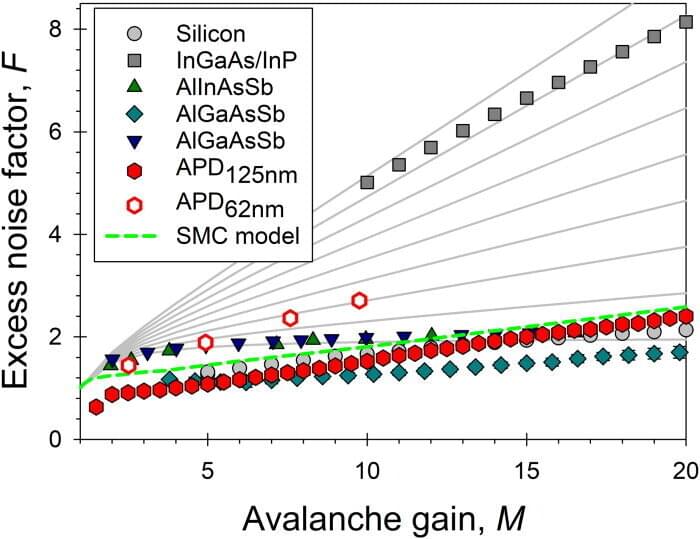

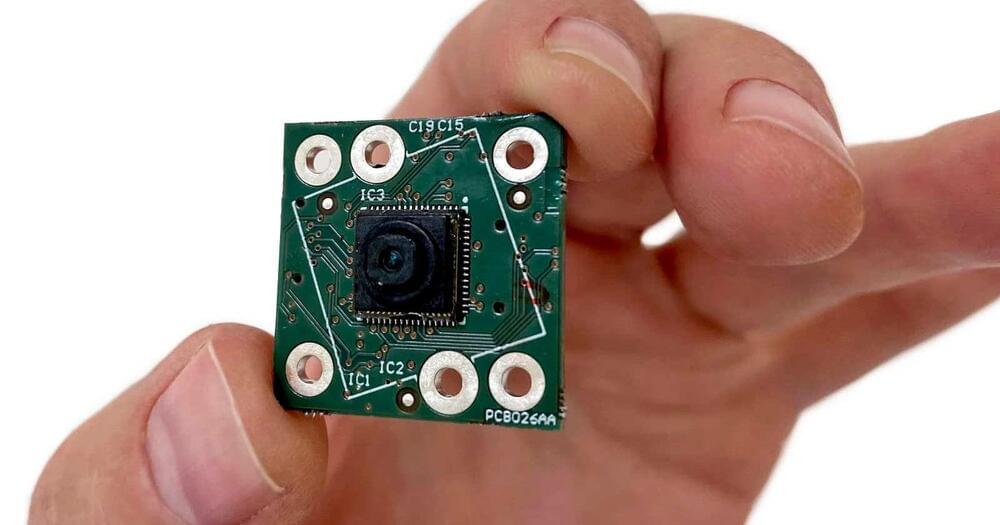

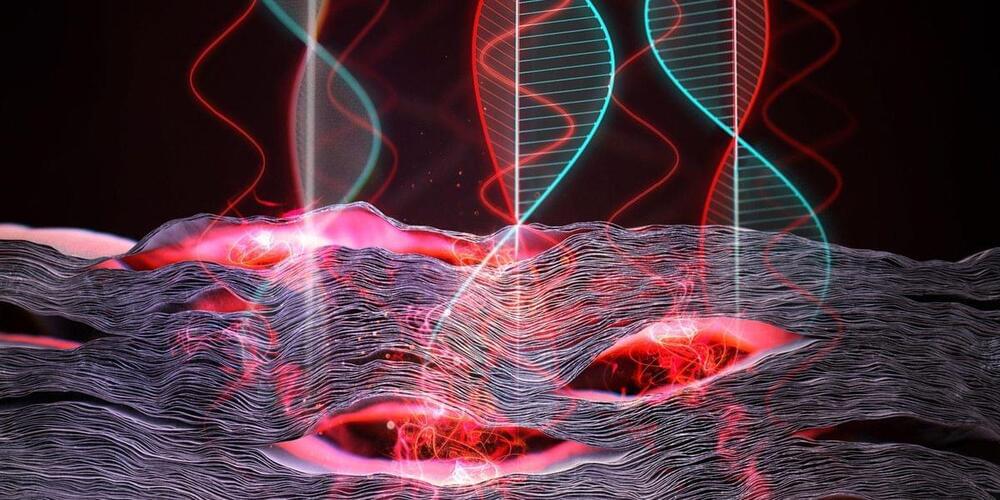

Optical pulses, which appear as a flash of light, are used to transmit information in high speed optical fibers, and are increasingly used in Light Detection And Ranging (LIDAR) for 3-dimensional imaging. Both of these applications demand light sensors or photodiodes that are capable of detecting very low levels of light intensity down to a few photons, where a single photon is the quantized energy unit of light.

A newly published paper, “Extremely low excess noise avalanche photodiode with GaAsSb absorption region and AlGaAsSb avalanche region,” in Applied Physics Letters, details a discovery by a Sheffield research team that has the capability to transform a single electron at its input to a cascade of electrons at its output.

This multiplication process is commonly known as avalanche breakdown, while a photodiode incorporating this process is called avalanche photodiode (APD). Though the application of reverse voltage, avalanche photodiodes (often referred to as APDs) have internal gain, which means that when compared to PIN-photodiodes they typically have a higher signal-to–noise ratio.

Samsung has earned a strong reputation among PC enthusiasts when it comes to solid-state storage. Its Pro series of SSDs are often among reviewers’ top recommendations for users seeking high-speed storage for large work files, apps, and boot drives. Over the past year, though, reliability concerns around Samsung’s 980 Pro and most recent 990 Pro have marred this reputation. It has become so notable that custom PC-maker Puget Systems, a top proponent of Samsung SSDs since the SATA days, has pulled 1TB and 2TB Samsung drives from its lineup.

For Puget, problems with Samsung SSDs, which the 22-year-old boutique PC shop sells in its custom-built systems, started with the 980 Pro that came out in September 2020. On January 31, Puget wrote a blog noting it received a surprising number of reports of failing Samsung drives, specifically with the 2TB version of the 980 Pro.

The most common failure mode that we have found is that the drives are suddenly locked into read-only mode, rendering the drive unusable. If the failed drive is the primary drive, then the system becomes unbootable until the drive is replaced and the OS is reinstalled, Chris Newhart, a Tier 2 repair technician at Puget, wrote.

Advanced new Faraday cages—the metal mesh enclosures that can block wireless signals—can also be switched on and off for reversible protection against noise, a new study finds.

In addition, these new shields can be easily fabricated through a technique akin to spray-painting, which could help them find use in electronics, researchers say.

Built out of a novel material called MXene, these cages could block and allow signals as desired.

Of the camera’s 580 photos, 400 were bear selfies.

The City of Boulder Open Space and Mountain Parks (OSMP) team in Colorado reported this week in a Tweet that an adorable bear was eager to strike a pose for wildlife motion capture cameras.

Making headlines around the world.

Boulder OSMP

“Recently, a bear discovered a wildlife camera that we use to monitor wildlife across Boulder open space,” OSMP Tweeted. “Of the 580 photos captured, about 400 were bear selfies.”