A new study from North Carolina State University shows a reproducible way of studying cellular communication among varied types of plant cells by “bioprinting” these cells via a 3D printer. Learning more about how plant cells communicate with each other—and with their environment—is key to understanding more about plant cell functions and could ultimately lead to creating better crop varieties and optimal growing environments.

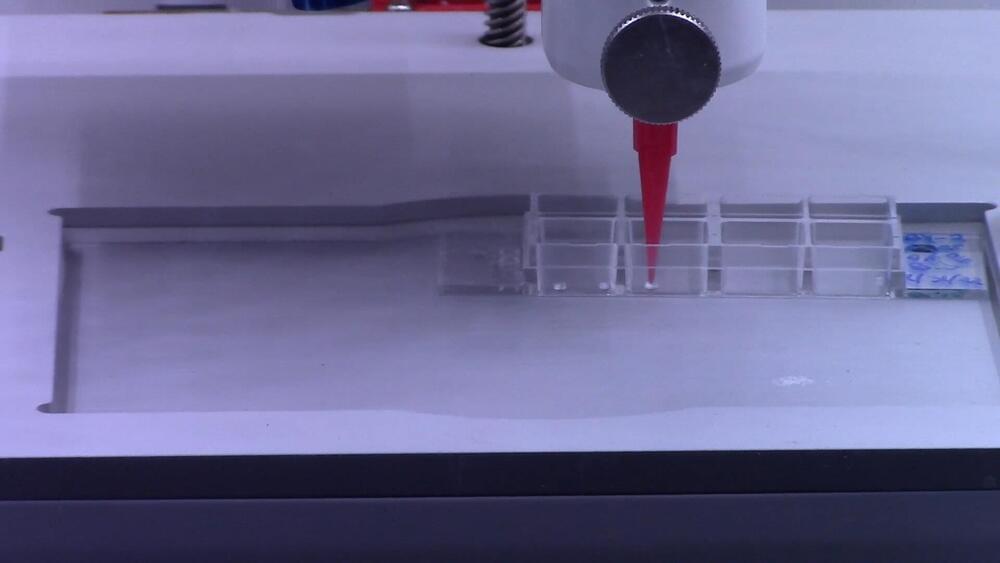

The researchers bioprinted cells from the model plant Arabidopsis thaliana and from soybeans to study not just whether plant cells would live after being bioprinted—and for how long—but also to examine how they acquire and change their identity and function.

“A plant root has a lot of different cell types with specialized functions,” said Lisa Van den Broeck, an NC State postdoctoral researcher who is the first author of a paper describing the work. “There are also different sets of genes being expressed; some are cell-specific. We wanted to know what happens after you bioprint live cells and place them into an environment that you design: Are they alive and doing what they should be doing?”