Good telescope that I’ve used to learn the basics: https://amzn.to/35r1jAk.

Get a Wonderful Person shirt: https://teespring.com/stores/whatdamath.

Alternatively, PayPal donations can be sent here: http://paypal.me/whatdamath.

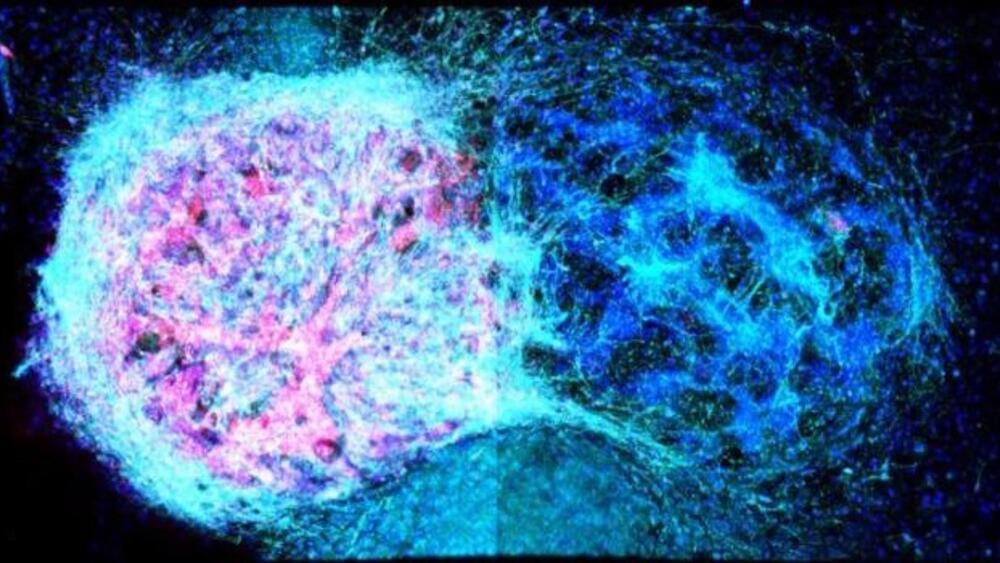

Hello and welcome! My name is Anton I’m away for a few days due to voice issues, so enjoy this older video where we talk about the incredible invention of 3D printed bio ink that could be used to print any biological tissue (in theory). 3D printed heart anyone?

Links:

https://www.nature.com/articles/s41467-021-26791-x.

https://www.mdpi.com/2072-666X/12/8/865

https://www.sciencedaily.com/releases/2021/09/210921134345.htm.

https://en.wikipedia.org/wiki/Fibrin.

Bladder grown from 3D bioprinted tissue continues to function after 14 years

https://www.ascb.org/science-news/bioprinting-ethical-and-societal-implications/

Biocomputing: https://youtu.be/nszcPNhYRzI

Artificial cell: https://youtu.be/0MRGJNKACYs.

Synthethic genome: https://youtu.be/OxVZPKmm58M

0:00 History of 3D printing organs.

2:00 Why this is important for medical studies.

2:45 Bioink invention.

3:40 How this works.

5:30 Results from the study are quite incredible.

6:30 Future of medical 3D printing.

Support this channel on Patreon to help me make this a full time job:

https://www.patreon.com/whatdamath.

Bitcoin/Ethereum to spare? Donate them here to help this channel grow!

bc1qnkl3nk0zt7w0xzrgur9pnkcduj7a3xxllcn7d4

or ETH: 0x60f088B10b03115405d313f964BeA93eF0Bd3DbF

Space Engine is available for free here: http://spaceengine.org.