ABERDEEN PROVING GROUND, Md. — Future American Soldiers will be better protected in combat by stronger and lighter body armor thanks to innovative work at the U.S. Army Research Laboratory. Materials science engineers are using nature as the inspiration for breakthroughs in additive manufacturing.

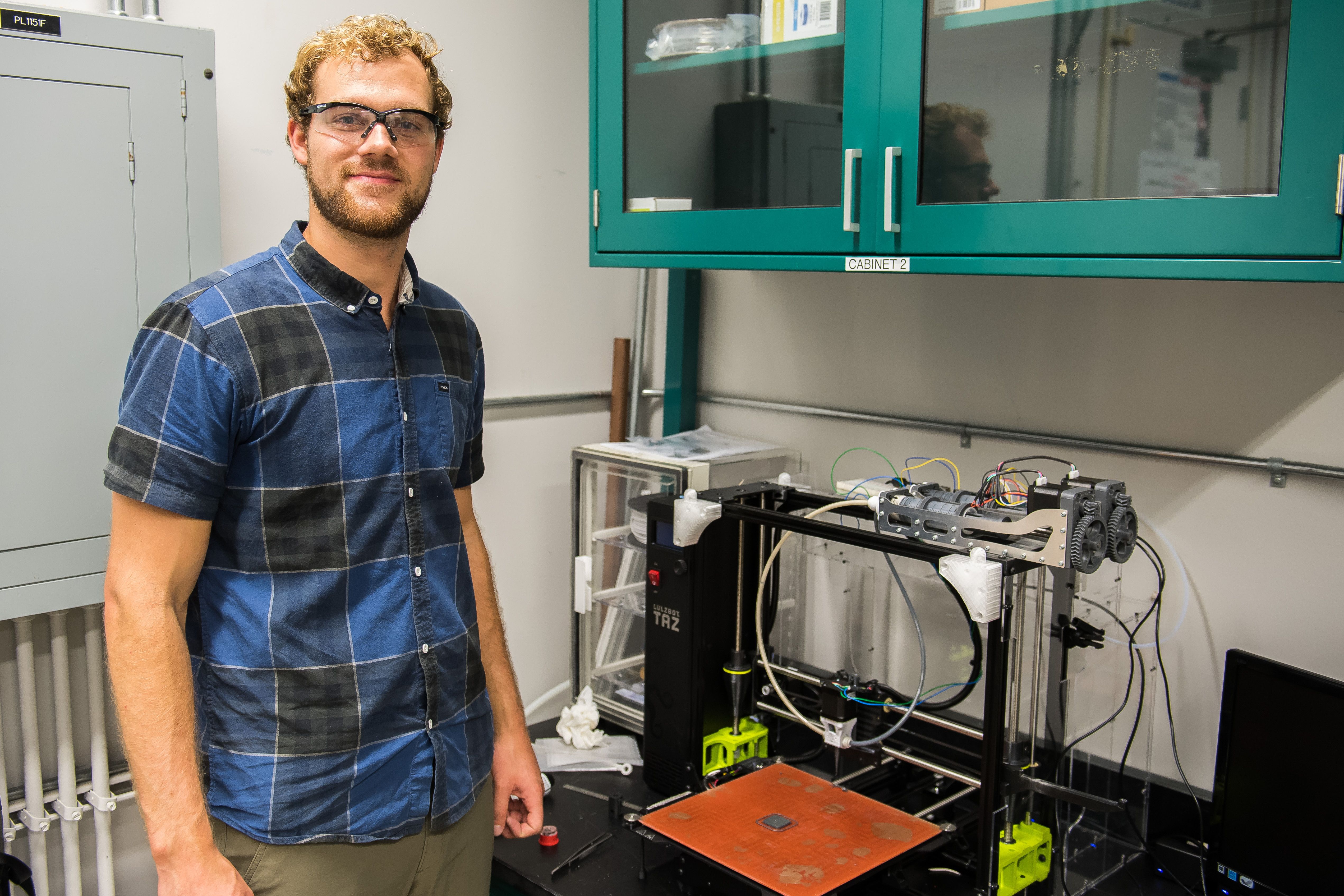

“My project is to design a system that can 3D print armor ceramics that will allow production of parts with graded structures similar to an abalone structure in nature that will improve the ceramic armor’s toughness and survivability with lower weight,” said Joshua Pelz, a materials science and engineering doctoral candidate at the University of California San Diego. He spent this summer working with Army scientists at ARL’s Rodman Materials Science Laboratory at APG to design and build a unique 3D printer.

Two syringes containing distinct, viscous ceramic slurries are connected to a custom-made auger and print head. Pelz took advantage of his computer programming skills to hack into the 3D printer, tricking it into using its own fan controls to manipulate the ratio of materials being printed. He designed a custom auger and print head and even used the same 3D printer to create those parts.